Blog

LiFePO4 Battery Cable Sizing Guide: Optimizing Performance and Safety

2026-01-18 | Calvin

As LiFePO4 batteries dominate the renewable energy and EV sectors due to their high energy density and thermal stability, many users overlook the "weakest link" in their system: the DC wiring.

Improperly sized cables lead to more than just inefficiency; they cause voltage sagging that can trigger BMS (Battery Management System) shutdowns and, in extreme cases, pose a significant fire hazard. To ensure your system operates at peak reliability, follow this technical breakdown for sizing LiFePO4 adapter cables.

1. Why Cable Sizing Matters for LiFePO4 Systems

Unlike lead-acid batteries, LiFePO4 batteries maintain a very flat discharge curve. However, they are capable of delivering extremely high current (C-ratings) almost instantly.

When a cable is too thin or too long, two physical phenomena occur:

- Resistance & Heat: Electrical resistance converts energy into heat. If the current exceeds the cable's Ampacity, the insulation can melt.

- Voltage Drop: A drop in voltage between the battery and the load. Since P = V X I, a lower voltage requires the equipment (like an inverter) to pull even more current to compensate, creating a dangerous feedback loop of heat.

2. The Two Golden Rules of Sizing

To meet professional standards (such as NEC or ABYC), you must size cables based on the stricter of these two criteria:

A. Ampacity (Safety)

The cable must be thick enough to handle the maximum continuous current without overheating.

B. Voltage Drop (Efficiency)

For 12V, 24V, or 48V systems, you should aim for a voltage drop of less than 3%. In high-precision setups, professionals aim for 1%.

3. How to Calculate the Required Cable Gauge

To determine the required Circular Mils (and thus the AWG), professionals use the following formula:

Cable Size (AWG) = (Length (ft.) x Current (A)) / (2 x (Voltage Drop (V)))

Where:

- AWG: American Wire Gauge, which is a standard used to determine the diameter of electrically conducting wire

- Length: The length of the cable in feet

- Current: The maximum current that the battery can deliver

- Voltage Drop: The maximum acceptable voltage drop across the cable

Example Calculation:

For example, if you have a LiFePO4 battery with a maximum current output of 100A and you want to use a cable that is 10 feet long with a maximum voltage drop of 0.1V:

Cable Size (AWG) = (10 x 100) / (2 x 0.1)

Cable Size (AWG) = 500

In this case, you would need a cable with a minimum AWG of 500, which is not a standard cable size. In practice, you would use the next largest standard cable size, which is typically AWG 000 (or 4/0).

4. Quick Reference: Ampacity & Gauge Table

The following table provides the maximum current (Ampacity) for copper cables rated at 90°C (194°F) insulation.

| Cable Gauge (AWG) | Cross Section (mm2) | Max Ampacity (Safety Limit) | Recommended Max Load (Continuous) |

|---|---|---|---|

| 10 AWG | 5.26 | 55A | 30A |

| 8 AWG | 8.37 | 80A | 50A |

| 6 AWG | 13.3 | 105A | 70A |

| 4 AWG | 21.2 | 140A | 100A |

| 2 AWG | 33.6 | 190A | 130A |

| 1/0 AWG | 53.5 | 260A | 170A |

| 2/0 AWG | 67.4 | 300A | 200A |

| 4/0 AWG | 107 | 405A | 300A |

Pro Tip: While a 10 AWG wire can technically handle 55A, using it at its limit over long distances will cause significant voltage drop. Always prioritize a larger gauge for runs exceeding 10 feet.

5. Critical Factors to Consider

When sourcing cables for LiFePO4 battery packs, keep these technical nuances in mind:

- Pure Copper vs. CCA: Never use Copper Clad Aluminum (CCA) for LiFePO4 systems. CCA has higher resistance and is prone to fatigue. Always insist on Oxygen-Free Pure Copper (OFC).

- Insulation Rating: Look for UL1015 or SGX ratings. High-quality silicone or EPDM insulation is preferred for its flexibility and resistance to high temperatures and chemicals.

- Environmental Derating: If your cables are routed through an engine bay or a hot enclosure (above 30°C/86°F), their current-carrying capacity decreases. You must "derate" the cable or choose one size larger.

Conclusion

Sizing cables for LiFePO4 batteries is a balance between electrical physics and safety standards. By calculating for both Ampacity and Voltage Drop, you protect your investment and ensure that your high-performance battery delivers every watt of power efficiently.

- Next:LiFePO4 Battery Troubleshooting Guide: Common Problems, Causes, and Proven Solutions

- Previous:3.7V Rechargeable Battery Guide

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- TC Elcon Charger (0)

- Headway Lithium Battery (6)

- Blade Battery (9)

- Semi Solid State Battery (6)

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (23)

- Cylindrical Cell (7)

- Energy Storage System (0)

- Battery Management System (5)

- Sodium ion Battery Cell (4)

- Lithium Titanate Battery (20)

- Ternary Lithium Battery Cell (11)

- REPT Battery (10)

- BYD Battery (2)

- CATL Battery (15)

- Thunder Sky Winston Battery (21)

- EVE Battery (30)

- LiFePO4 Battery Cell (4)

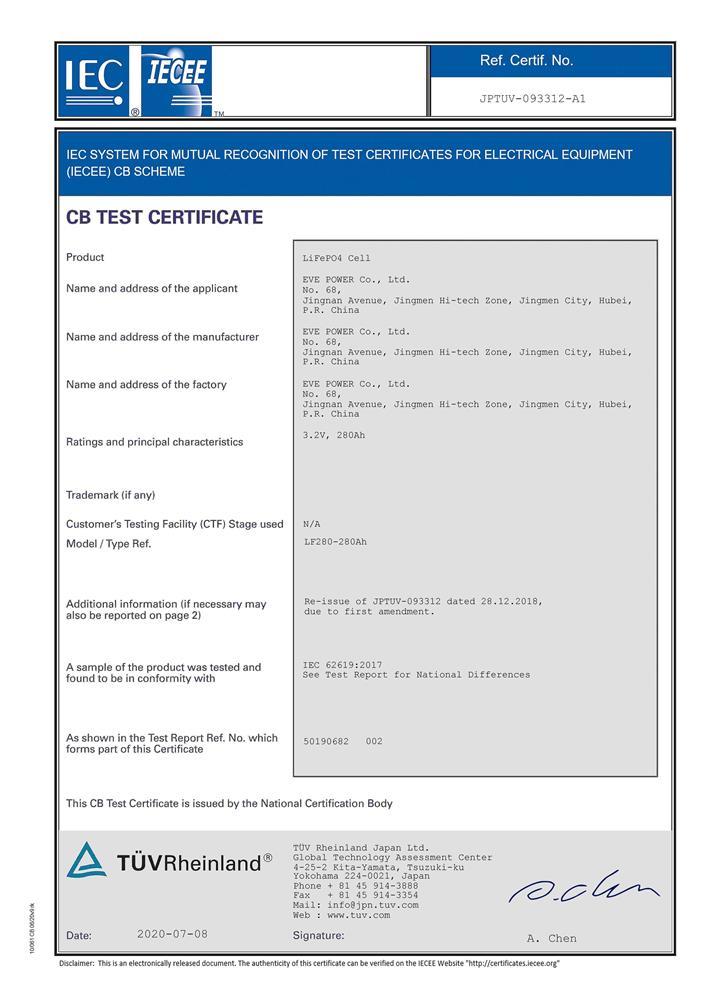

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia