Blog

Latest Trends in Large-Capacity Energy Storage Cells

2026-01-26 | Calvin

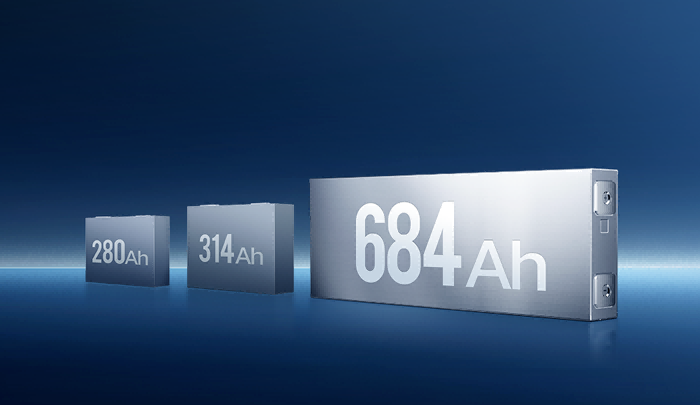

As the global energy mix accelerates its transition toward renewable energy, energy storage systems have become a critical component for balancing grid fluctuations and improving the utilization of green electricity. Against this backdrop, the need to reduce costs and improve efficiency in energy storage systems is becoming increasingly urgent. Large-capacity battery cells have therefore emerged as a key focus of industry competition—from 280Ah and 314Ah to 500Ah+, and even 600Ah+ products, with iteration cycles shortening significantly. However, while large-capacity cells help reduce system costs, they also face a series of technical challenges and must undergo rigorous validation by investors regarding full lifecycle safety and economic performance. This article analyzes the underlying logic and future trajectory of large-capacity cell development from technical, market, and manufacturing perspectives.

01. Landscape of Large-Capacity Cell Deployment

As the demand for cost reduction and efficiency improvement in energy storage intensifies, battery cells are evolving toward larger capacities. At present, nearly 20 cell manufacturers have launched 500Ah+ large-capacity cell products or related development plans, and the pace of cell iteration continues to accelerate.

The transition of energy storage cells from 280Ah to 300+Ah took approximately three years, while the leap from 300+Ah to 500Ah—and even 600Ah—has occurred within just two years.

CATL has consolidated its leading position in large-scale energy storage power plants through its 587Ah cell, attempting to enhance customers’ comprehensive service capabilities by setting a “high-capacity standard.” Sungrow, acting as a system integrator, has reverse-defined a 684Ah cell, building differentiated competitiveness through coordinated “cell–system” design. CALB and REPT have focused on the 392Ah specification to seek rapid market entry.

While increasing cell capacity has become an industry-wide trend among cell manufacturers and system integrators, whether project investors truly recognize and accept large-capacity cells remains uncertain. Continuous market validation is required to distinguish the true capabilities of large-capacity cells.

02. Why Develop Large-Capacity Cells

Battery cells represent the most valuable component of the entire energy storage system and are the primary battlefield for continuous innovation in storage integration technology. They directly determine system grouping methods and integration solutions.

The core rationale behind large-capacity cells is to reduce the number of batteries, auxiliary components, and land usage in energy storage systems by increasing single-cell capacity, thereby lowering the overall investment cost of energy storage power plants.

For example, CATL’s 587Ah cell can reduce the number of system components by 20% and increase space utilization by 30%. Fewer cells also mean significant cost reductions in connectors, fuses, BMS sensing harnesses, and other auxiliary materials.

From an operations and maintenance perspective, for energy storage systems of the same capacity, large-capacity cells significantly reduce the total number of cells, which in turn reduces potential failure points. This lowers monitoring and maintenance complexity and reduces full lifecycle O&M costs.

03. Technical Challenges Faced by Large-Capacity Cells

During charging and discharging, when cell capacity exceeds 500Ah, electrode thickness must increase from approximately 150μm to 250μm. This extends the diffusion distance of Li⁺ ions within the LiFePO₄ lattice, hindering internal electrochemical reactions. As a result, polarization voltage rises toward the end of charging, accelerating cell aging and shortening service life. Moreover, increased polarization voltage at the end of charging generates excess heat inside the cell, potentially triggering thermal runaway and leading to safety incidents such as fires or explosions.

From a manufacturing perspective, electrodes require extremely high coating uniformity. As electrode size increases, thickness deviation also increases. Large-capacity cells have larger tab welding areas, increasing the probability of cold welds or burn-through. During the formation process, uneven current distribution can lead to inconsistencies in SEI film formation, affecting lifecycle consistency.

In system integration, the challenges of large-capacity cells center on refined management and risk control. In large-cell systems, the importance of each individual cell increases significantly. In a 314Ah system, failure of a single cell affects only about 0.3% of cluster capacity, whereas in a 684Ah system, a single-cell failure may impact around 0.6% of cluster capacity. Large cells also have longer heat dissipation paths and higher thermal resistance, making it difficult for heat to be quickly transferred to the outside. This places higher requirements on the reliability of thermal management design. To improve heat dissipation, higher-flow and higher-pressure liquid cooling pumps are required to ensure rapid coolant circulation, and related thermal components must provide greater cooling capacity and reliability.

On the application side, 314Ah-based systems are already very mature. For investors, the safety, lifespan, and stability of large-capacity cell integration solutions are currently validated mainly through equipment suppliers’ test reports, lacking reliable long-term operational data. The actual operating performance of large-capacity cells remains uncertain, making near-term adoption more challenging.

Therefore, large-scale application of large-capacity cells will not happen overnight. Cell manufacturers will comprehensively consider process complexity, costs, and market acceptance, while investors will evaluate safety, economic performance, and ease of cell replacement.

04. Manufacturing Processes

Due to differences in R&D focus and technical accumulation among companies, divergent approaches have emerged in the manufacturing of large-capacity cells. Currently, two main process routes dominate the production of 500Ah+ cells: winding and stacking.

Advantages of the stacking process: Stacked electrode assemblies feature a layered structure with no electrode bending, allowing more efficient use of internal casing space. Compared with winding, stacking offers higher energy density, lower internal resistance, lower temperature rise, better rate performance, and improved safety.

Disadvantages of the stacking process: Electrodes must be cut and then stacked, and the cut edges may have burrs and dust, posing a risk of internal short circuits. High precision is required for burr control and alignment, necessitating semi-automatic or fully automatic high-precision equipment, which increases equipment and production costs.

Advantages of the winding process: The core is formed through high-speed rotation, involving fewer mechanical actions and shorter auxiliary time, resulting in high production efficiency. Winding requires only two spot welds per cell, making the process relatively simple. Winding machines are relatively inexpensive, leading to lower capital investment.

Disadvantages of the winding process: Since wound cells typically have only a single positive and negative tab, part of the voltage is consumed by internal polarization, resulting in poorer charge/discharge rate performance. During winding, uneven tension on electrodes and separators can cause wrinkles, and repeated expansion and contraction of electrodes can negatively affect cycle life.

05. Standardization or Differentiation of Specifications

Following the release of China’s Document No. 136, the market-oriented operation of energy storage power plant investments has accelerated, with investors placing greater emphasis on full lifecycle economics. Industry consensus has formed around “thermal runaway warning thresholds” and “minimum cycle life requirements,” providing safety baselines for system adaptation across different cell sizes. Meanwhile, communication protocols and monitoring parameters between BMS and cells are becoming increasingly standardized, allowing cells of different sizes to be integrated into the same monitoring system.

Against this backdrop, the evolution of energy storage cell sizes is not a binary choice between standardization and differentiation, but rather a dynamic process that preserves differentiated innovation within a unified framework.

In the short term, differences in market priorities—capacity, energy density, cost, and safety—are driving design divergence. Cells such as 314Ah, 392Ah, and 500Ah+ will form a complementary competitive landscape. The 314Ah and 392Ah cells will continue to dominate the 2-hour and 4-hour storage markets, while 500Ah+ cells will focus on long-duration storage of 4 hours and above.

In addition, intensifying market competition has led cell manufacturers at different market positions to adopt differentiated strategies. Leading companies tend to focus on a single specification to redefine the next generation of cell size, while second- and third-tier companies adopt multi-specification strategies to meet diverse customer needs. This has resulted in increased short-term diversification of cell sizes and a flourishing, multi-specification landscape.

In the long term, as storage duration requirements increase and large-cell manufacturing processes mature, cells such as 530Ah, 587Ah, and 684Ah will be tested by their performance across different markets and their impact on plant-level and system-level design. Integrators will select appropriate technical paths based on these factors, further reinforcing size diversity. Winding processes, with lower overall manufacturing costs, are likely to focus on markets below 600Ah, while stacking processes—offering more uniform internal stress distribution and lower heat generation—will target the 600Ah+ segment.

06. Outlook on Future Trends

Cell development should not focus solely on increasing capacity; investor acceptance must also be considered. Therefore, the development of large-capacity cells should start from the perspective of the entire energy storage system, including AC-side power distribution and long-term operation and maintenance, exploring technological innovation pathways to reduce LCOS.

Although large-capacity cells ranging from 500Ah+ and 700Ah+ to even 1000Ah+ are being introduced one after another, large-scale deployment has not yet been achieved. It is still too early to determine which product will become the next mainstream solution. Ultimately, the winning cell type will depend on companies’ deep understanding of system boundaries, rational judgment of technological thresholds, and flexible response to application scenarios.

- Next:Everything You Need to Know About Bad Battery Cells

- Previous:LiFePO4 Battery Charging FAQ: What You Need to Know

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- TC Elcon Charger (0)

- Headway Lithium Battery (6)

- Blade Battery (10)

- Semi Solid State Battery (6)

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (23)

- Cylindrical Cell (8)

- Energy Storage System (0)

- Battery Management System (5)

- Sodium ion Battery Cell (4)

- Lithium Titanate Battery (20)

- Ternary Lithium Battery Cell (11)

- REPT Battery (10)

- BYD Battery (2)

- CATL Battery (15)

- Thunder Sky Winston Battery (21)

- EVE Battery (30)

- LiFePO4 Battery Cell (7)

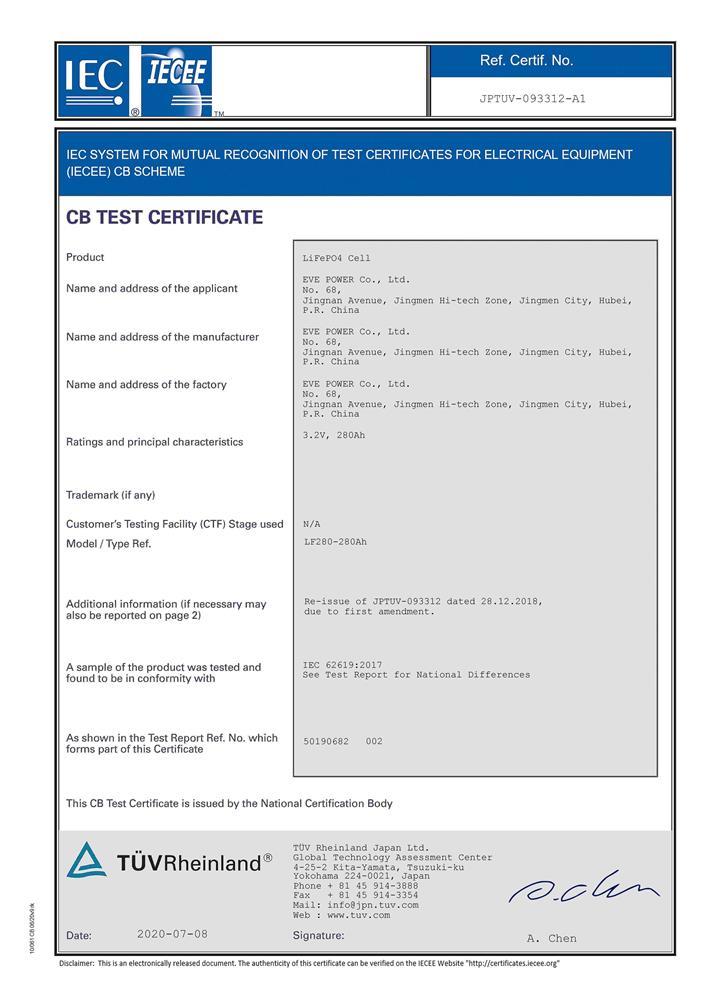

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia