Blog

The Advantages of Lithium-Ion Batteries in Forklifts: A Smarter Power Choice for Modern Warehouses

2025-12-31 | Calvin

Forklifts are the backbone of warehouses, factories, and distribution centers. Behind every reliable forklift, there’s one critical component doing the heavy lifting quietly—the battery. For decades, lead-acid batteries dominated this space. But times have changed. Today, lithium-ion forklift batteries are quickly becoming the preferred choice for businesses that value efficiency, performance, and long-term savings.

So, what’s driving this shift? Let’s break it down in a clear, practical way.

What Are Lithium-Ion Forklift Batteries?

Lithium-ion batteries are advanced energy storage systems that use lithium compounds to store and release electrical energy. In forklift applications, the most common type is LiFePO4 (Lithium Iron Phosphate), known for its safety, stability, and long lifespan.

Unlike traditional lead-acid batteries, lithium-ion units are sealed, maintenance-free, and controlled by an intelligent Battery Management System (BMS) that continuously monitors performance and safety.

Key Advantages of Lithium-Ion Batteries in Forklifts

1. Faster Charging, No Downtime

One of the biggest advantages is charging speed.

- Lithium-ion forklift batteries can charge to 80% in 1–2 hours

- Opportunity charging during breaks is safe and does not damage the battery

- No need for battery swapping or dedicated charging rooms

For operations running multiple shifts, this alone can dramatically increase uptime and productivity.

2. Longer Battery Life and Lower Total Cost

Lithium-ion batteries typically last 3–5 times longer than lead-acid batteries.

- Lead-acid: ~1,200–1,500 cycles

- Lithium-ion: 3,000–5,000+ cycles

While the upfront cost is higher, the total cost of ownership (TCO) is often significantly lower due to fewer replacements, reduced labor, and minimal maintenance.

3. Maintenance-Free Operation

Say goodbye to daily battery maintenance.

With lithium-ion batteries:

- No watering

- No acid spills

- No corrosion

- No equalization charging

This not only saves labor costs but also improves workplace safety and cleanliness—an often overlooked benefit in busy warehouses.

4. Consistent Power and Better Performance

Lithium-ion batteries deliver stable voltage throughout the entire discharge cycle. That means:

- Forklifts maintain consistent speed and lifting power

- No sluggish performance near the end of a shift

- Improved operator confidence and efficiency

In contrast, lead-acid batteries gradually lose power as they discharge, slowing operations when it matters most.

5. Improved Energy Efficiency

Lithium-ion batteries are highly efficient, with energy efficiency rates above 95%, compared to around 70–80% for lead-acid.

What does this mean in real terms?

- Lower electricity consumption

- Reduced heat loss during charging

- Smaller carbon footprint

For companies focused on sustainability and energy savings, this is a major win.

6. Enhanced Safety with Smart BMS Technology

Modern lithium-ion forklift batteries come equipped with advanced Battery Management Systems (BMS) that provide:

- Overcharge and over-discharge protection

- Temperature monitoring

- Short-circuit prevention

- Real-time diagnostics

These built-in safety features significantly reduce the risk of battery failure, overheating, or accidents, making lithium-ion one of the safest power solutions available today.

7. Space-Saving and Flexible Design

Lithium-ion batteries are:

- More compact

- Lighter in weight

- Customizable to fit specific forklift models

This allows for better vehicle balance and more flexible equipment design, especially in narrow-aisle or high-density warehouse environments.

Lithium-Ion vs Lead-Acid: A Quick Comparison

| Feature | Lithium-Ion | Lead-Acid |

|---|---|---|

| Charging Time | 1–2 hours | 8–10 hours |

| Maintenance | None | Regular watering |

| Battery Life | 3,000–5,000 cycles | 1,200–1,500 cycles |

| Energy Efficiency | 95%+ | 70–80% |

| Opportunity Charging | Yes | Not recommended |

| Safety | High (BMS controlled) | Moderate |

Are Lithium-Ion Forklift Batteries Right for You?

Lithium-ion batteries are especially suitable for:

- High-throughput warehouses

- Multi-shift operations

- Cold storage facilities

- Businesses aiming to reduce long-term operating costs

- Companies focused on safety and sustainability

If your operation depends on efficiency, uptime, and predictable performance, lithium-ion is no longer a “future option”—it’s a practical solution available today.

Conclusion

Switching to lithium-ion batteries in forklifts isn’t just about upgrading power—it’s about upgrading your entire operation. From faster charging and zero maintenance to longer lifespan and better safety, the advantages are clear.

As warehouse automation and efficiency demands continue to grow, lithium-ion technology stands out as a smart, future-ready investment.

- Next:4 Ways of RV Battery Charging: A Practical Guide for Reliable Power on the Road

- Previous:Functions and Applications of a Battery Management System (BMS)

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- Headway Lithium Battery (6)

- Blade Battery (8)

- Semi Solid State Battery (6)

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (6)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (4)

- Lithium Titanate Battery (20)

- Ternary Lithium Battery Cell (11)

- REPT Battery (10)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (30)

- LiFePO4 Battery Cell (4)

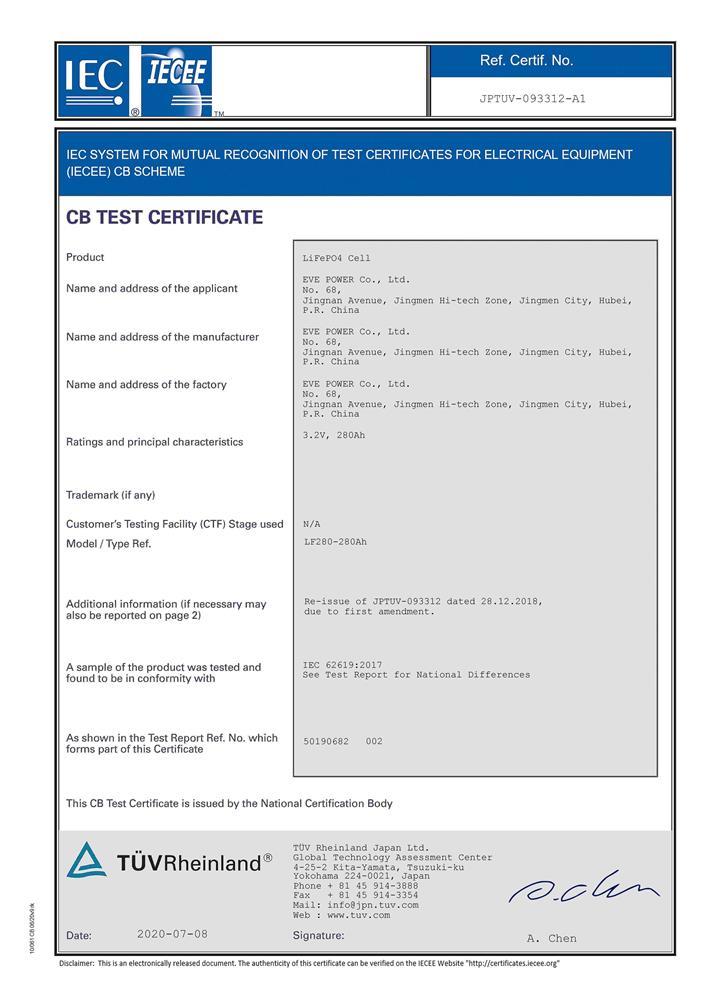

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia