News

SVOLT Unveils “BeeShield 4.0 Safety Grading System” for the First Time, Setting a New Industry Benchmark for Battery Safety

2025-11-18 | Calvin

On November 12, 2025, the 4th World Power Battery Conference was grandly opened in Yibin, Sichuan, hosted by the People's Government of Sichuan Province and co-organized by the Yibin Municipal Government, the Department of Economy and Information Technology, and the Equipment Industry Development Center of the Ministry of Industry and Information Technology. SVOLT Chairman and CEO Yang Hongxin delivered a keynote report on “Semi-Solid Industrialization and Battery Application Safety Grading System” and officially introduced the BeeShield Safety Grading System at the conference.

From Cell Safety to System Safety to Full-Scenario Application Safety: SVOLT Establishes the “BeeShield Battery Safety Grading System”

Yang Hongxin stated that safety is not only an intrinsic design at the cell level but also requires comprehensive protection at the system level. SVOLT proposed, for the first time, the BeeShield Battery Safety Grading System centered on “thermal runaway prevention capability,” defining the safety of each generation according to application scenarios and quantifying it through specific cell and system metrics.

SVOLT began developing battery safety technology as early as 2019. BeeShield 1.0 focused on normal usage scenarios; BeeShield 2.0 ensured personnel safety in emergency scenarios; BeeShield 3.0 had already fully met all requirements of the “Safety Requirements for Power Batteries for Electric Vehicles” issued by the Ministry of Industry and Information Technology in March this year. Compared to BeeShield 3.0, BeeShield 4.0 represents an all-dimensional improvement in intrinsic, passive, and active safety.

Regarding intrinsic safety, semi-solid technology reduces the probability of thermal runaway. In terms of passive safety, the “Dragon Scale Armor” design achieves thermal-electrical separation, limiting system thermal propagation and providing advantages such as:

1. Preventing thermal runaway flames from directly impacting the vehicle chassis or passenger cabin;

2. Keeping ejected materials away from cell terminals and high-voltage electrical components, reducing the risk of short-circuit arcing;

3. Preventing damage to sensors and control units from compromising water-cooling suppression strategies.

For active safety, a full-lifecycle AI model iterates over existing cell mechanisms, enhancing early warning accuracy.

Through the establishment of the BeeShield Safety Grading System and the implementation of BeeShield 4.0, SVOLT has successfully transformed battery safety from an abstract concept into a clear, measurable engineering practice. This not only systematically builds a three-dimensional safety shield of intrinsic, passive, and active protection but also redefines power battery safety with industry-leading transparency, providing users with reliable protection across the entire product lifecycle.

“Electrolyte Thermal Composite Transfer Process”: Key to Rapid Commercialization of Semi-Solid Batteries

Currently, ternary batteries remain the top choice in high-end and emerging markets, yet thermal runaway in ternary batteries accounts for up to 70% of EV fire incidents. In intrinsic safety, SVOLT addresses ternary lithium battery thermal stability using semi-solid technology, introducing non-flammable, non-corrosive solid electrolytes to enhance safety without sacrificing performance or increasing manufacturing costs. The world’s first “Electrolyte Thermal Composite Transfer Process” offers a technical solution for the rapid mass production of semi-solid batteries with enhanced safety.

This process leverages material innovations—such as optimized diaphragm adhesive layers and semi-solid coating formulations—and production parameter design to achieve nanometer-level protection of electrodes, replacing traditional cathode surface coating technology.

During development, SVOLT overcame two major challenges: first, the innovative “polarity conversion adhesive solution” achieved efficient transfer of the coating from base film to electrode, raising transfer rates from about 20% to over 95%; second, the custom “profiled gradient hot-press technology” resolved coverage consistency issues caused by uneven electrode thickness.

The process is 100% production line compatible and requires no additional investment, making it “the industry’s lowest-cost, fastest semi-solid battery mass production solution.” Cells produced using this method achieve 100% thermal runaway prevention, a 50% reduction in leakage current under short-circuit conditions, and an 18.5% decrease in full-lifecycle pressure failure rate, enhancing product consistency, safety, reliability, durability, and stability.

In semi-solid battery mass production planning, SVOLT has established a 2.3GWh dedicated semi-solid battery production line and completed the development of the first-generation 270Wh/kg prismatic cell, with C-sample batch trials imminent. This product has already secured orders from well-known European EV brands and a key eVTOL project with a state-owned enterprise. By 2026, the first-generation semi-solid battery will achieve mass production ramp-up; the second-generation 400Wh/kg prismatic cell will be developed; by 2028, the 450Wh semi-solid pouch cell will be completed.

SVOLT’s technological breakthroughs in semi-solid batteries not only secure a performance “technological high ground” but also establish the industry’s “safety cornerstone” through graded battery safety. This enhances corporate competitiveness while promoting transparency and a trusted technology system, driving sustainable development across the entire industry chain. Against the backdrop of global supply chain restructuring, these two core technologies will lay a solid foundation for national energy security and industrial resilience.

- Next: Electric Autonomous Driving Reshapes Mine Transportation! CATL and Easy Control Intelligent Driving Sign Strategic Agreement

- Previous: Sunwoda’s Consumer Semi-Solid-State Battery Production Exceeds 8 Million Units

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

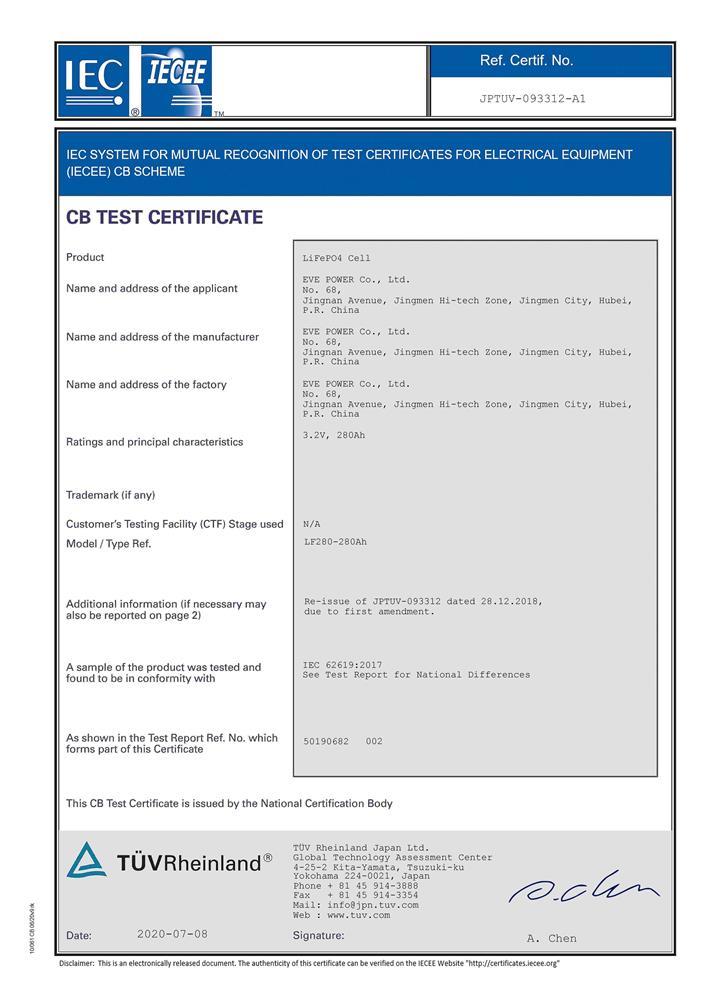

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia