News

CATL Launches Revolutionary Ultra-Safe Bedrock Chassis

2025-09-03 | Calvin

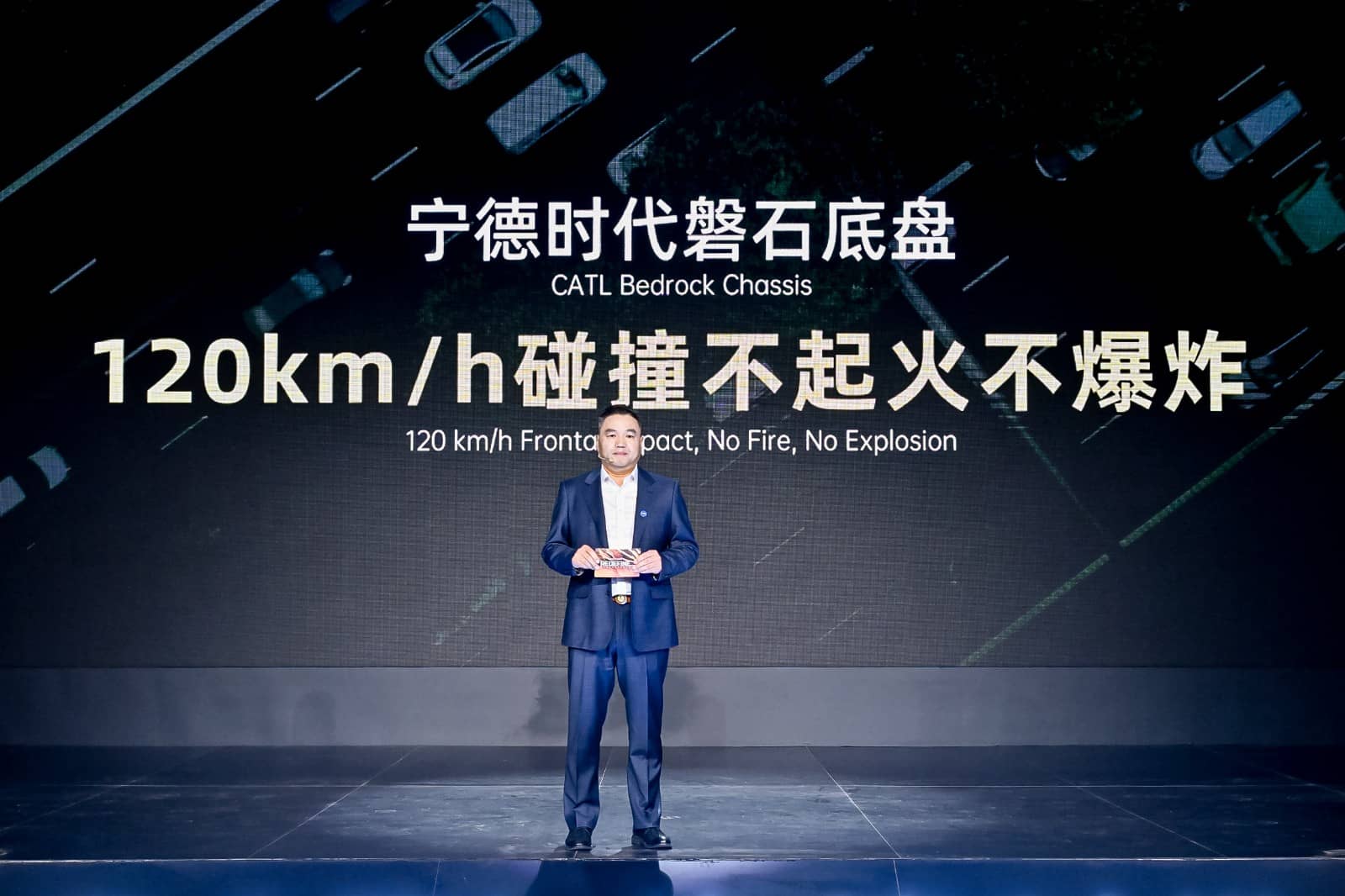

December 24, 2024 — CATL officially launched the CATL Bedrock Chassis, the world's first ultra-safe skateboard chassis. Setting a new benchmark for intelligent chassis safety, the Bedrock Chassis withstands frontal impacts at 120 km/h without fire or explosion, delivering comprehensive protection across all driving scenarios and speed ranges.

Industry-Leading Safety Performance

Designed with a battery-centric approach, the CATL Bedrock Chassis utilizes Cell-to-Chassis (CTC) integration technology, embedding cells directly into the chassis to create a unified structural system. Decoupled from the vehicle's upper body, the chassis absorbs up to 85% of collision energy—significantly higher than the approximate 60% absorbed by conventional chassis systems.

Through multiple technological breakthroughs, the Bedrock Chassis has passed the world’s first dual-extreme safety test, combining the highest speed and strongest impact conditions. It successfully withstood a 120 km/h frontal central pole impact without fire, explosion, or thermal runaway—redefining safety standards in the automotive industry.

For context, the current C-NCAP (China New Car Assessment Program) frontal impact test is conducted at 56 km/h, equivalent to the energy of a fall from a 12-meter height. An impact at 120 km/h corresponds to a fall from 56 meters, generating 4.6 times more energy.

In more demanding frontal pole crash tests—which simulate collisions with narrow objects like utility poles or trees—the impact area is only one-sixth that of a full-width impact, dramatically increasing localized pressure. At 120 km/h, unit-area pressure reaches 21 times that of a C-NCAP 56 km/h full-width impact.

No electric vehicle has previously attempted a 120 km/h frontal pole impact test. CATL’s Bedrock Chassis is the first to conquer this extreme challenge, paving a new path for vehicle safety.

Three Core Technological Breakthroughs

The Bedrock Chassis incorporates innovations in structure and materials to ensure uncompromising safety:

- Biomimetic Tortoise Shell Structure: A deeply integrated body and energy unit framework inspired by natural protection mechanisms.

- Aircraft Carrier-Grade Arresting System: Multi-path dispersion of impact forces slows intrusion speed and depth during collisions.

- Advanced Materials: Submarine-grade hot-formed steel (2000MPa), aerospace-grade aluminum alloy (600MPa), and multi-layer barriers enhance structural rigidity.

The chassis also features an ultra-safe cell design, NP (no propagation) technology, and a high-ductility insulation film. Its high-voltage disconnection system cuts power within 0.01 seconds of impact and discharges residual energy within 0.2 seconds—setting a new industry benchmark.

CATL battery cells have passed extreme tests including 60 km/h high-speed sled impacts, 90-degree bending, and breakthrough sawing tests—without fire or explosion in any scenario.

Unlocking Customization and Trillion-Yuan Market Potential

The Bedrock Chassis not only raises safety standards but also accelerates the shift toward modular, personalized, and intelligent vehicle architectures. It addresses industry challenges such as high R&D costs, long development cycles, and rapid product iteration.

With its three core features—internal integration, chassis-body decoupling, and external openness—the chassis supports a “one architecture, multiple models” strategy. Standardized interfaces and scalable hardware/software toolkits allow flexible adaptation across vehicle types and use cases, reducing time-to-market from 36+ months to just 12–18 months.

The fourth-generation CTC technology and inverted cell design improve space utilization and reduce scraping risks. The chassis also supports mechanical, software, and electrical/electronic (EE) decoupling, enabling L3–L4 autonomous driving capabilities and intelligent application integration.

At the launch event, AVATR Technology became the first automaker to adopt the Bedrock Chassis, signing a cooperation agreement with CAIT-SH (CATL's skateboard chassis division) to develop safer, higher-quality electric vehicles.

“Safety is a never-ending journey,” said a CATL representative. “We will continue to innovate and collaborate with partners to build a secure ecosystem for electric vehicles and ensure user safety worldwide.”

- Next: HiTHIUM 587Ah Ultra High Capacity Battery Enters Mass Production and Completes First Delivery

- Previous: Robin Zeng: Musk’s Bet on Cylindrical Batteries Will Fail

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

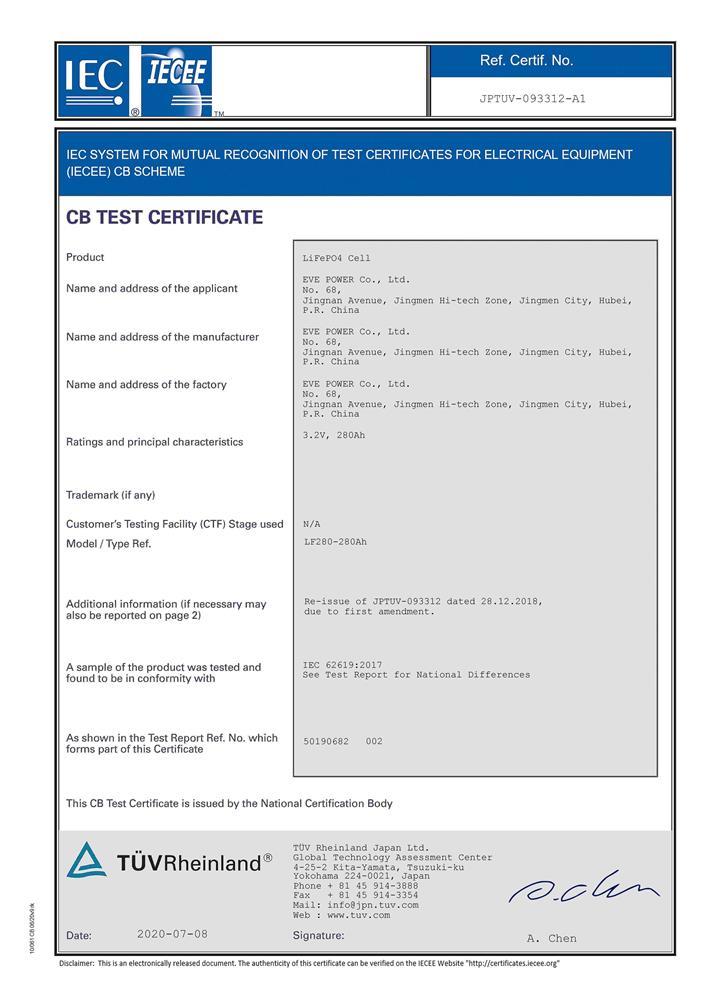

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia