Blog

Three Common Inverter Faults and Solutions

2025-06-03 | Calvin

In a photovoltaic (PV) power generation system, the inverter plays a crucial role by converting the direct current (DC) generated by the PV panels into alternating current (AC) to meet the power needs of households, businesses, or the grid. However, inverters may encounter various faults during operation. Below is an in-depth analysis of the three most common inverter issues, aiming to provide users with practical technical support.

1. Abnormal Input Voltage

- Fault Symptoms:

- The inverter fails to start properly or suddenly stops working during operation, displaying fault codes indicating that the input voltage is too high or too low, which affects the normal power generation of the PV system.

- Possible Causes:

-

- PV Panel Issues: Panels may be shaded, accumulate dust on the surface, or have damaged internal cells, causing unstable output voltage or voltage levels below the normal range. Additionally, loose or poor connections in the junction box of the panel can also affect the voltage output.

- Connection Line Faults: The DC cables between the panels and the inverter may be damaged, short-circuited, open-circuited, or poorly connected, obstructing voltage transmission or causing abnormal drops.

- Solutions:

-

- Check the PV Panels: Regularly clean the panel surfaces to remove dust and debris, and ensure there are no shading obstructions. Use professional PV testing equipment such as an IV curve tester to check the output characteristics of the panels. Replace any damaged panels promptly. Additionally, tighten the connections inside the panel junction box to ensure reliable connections.

- Inspect Connection Lines: Carefully examine the appearance of the DC cables for damage or signs of aging. For loose connections, retighten the terminals; for short-circuited or open-circuited cables, promptly repair or replace them.

2. Abnormal Output Voltage or Frequency

- Fault Symptoms:

- The inverter outputs AC voltage that is too high or too low, and the frequency is unstable, exceeding the normal allowable range. This may cause connected electrical devices to malfunction or even damage them, and it can also affect grid stability.

- Possible Causes:

-

- Internal Control Circuit Faults: Electronic components in the control circuit, such as capacitors, resistors, and transistors, may experience aging, damage, or poor soldering, affecting the inverter's ability to control output voltage and frequency accurately.

- Sudden or Mismatched Load: When a large load change occurs, such as multiple high-power loads starting or stopping simultaneously, or if the load has a low power factor or high harmonic content, the inverter may exceed its adjustment capacity, causing output voltage and frequency abnormalities.

- Grid Voltage Fluctuations: Sudden increases or decreases in grid voltage beyond the inverter's allowable output voltage range can also cause this fault.

- Solutions:

-

- Check the Inverter's Internal Control Circuit: Open the inverter housing (under professional guidance to ensure safety) and use tools such as oscilloscopes and multimeters to inspect key components in the control circuit. Replace any damaged components with the original specifications and check for poor soldering on the circuit board.

- Optimize Load Configuration: Arrange load connections and usage carefully, avoiding simultaneous startup or shutdown of large loads. For low power factor inductive loads, consider installing reactive power compensation devices such as capacitor compensation cabinets to improve the power factor; for nonlinear loads with high harmonic content, install filters at the load's front end to reduce harmonic interference on the inverter's output.

- Monitor Grid Voltage: Install a grid voltage monitoring device to track real-time voltage fluctuations. If frequent or abnormal grid voltage fluctuations occur, contact local grid authorities for assistance in resolving the issue.

3. Low Insulation Resistance or Leakage Current Fault

- Fault Symptoms:

- The inverter displays an alarm indicating low insulation resistance, or during electrical safety testing, leakage current is detected. This not only affects the normal operation of the inverter but may also pose a safety threat to personnel.

- Possible Causes:

-

- DC Cable Damage: Over time, the DC cables may be subjected to external forces, wear, aging, or rodent damage, causing the insulation layer to fail, which leads to a decrease in insulation performance between the positive and negative terminals or between the DC terminals and the ground, resulting in leakage current faults.

- Poor Grounding of the PV Panels: If the metal frames of the PV panels are poorly grounded, corroded, or have high grounding resistance, it can create a potential difference between the panels and the ground, generating leakage current. Additionally, if the mounting bracket is not securely connected to the grounding system, this may also lead to poor grounding.

- Humid Installation Environment: If the inverter is installed in a humid, water-prone environment, moisture may intrude into the inverter or accumulate on the DC cables and panel surfaces, reducing the insulation properties of the materials and causing low insulation resistance and leakage current faults.

- Solutions:

-

- Inspect DC Cables: Carefully check the appearance of the DC cables along their path for signs of damage, cuts, wear, or aging. For minor damage, use insulation tape to repair; for severe damage, replace the cables promptly. Regularly use an insulation resistance tester to measure the insulation resistance of the DC cables to ensure compliance with requirements.

- Ensure Proper Grounding of Panels: Check the grounding connections of the PV panels to ensure they are secure and that the grounding wires are free from breakage or corrosion. Use a grounding resistance tester to measure the grounding resistance of the panels, ensuring it is below 4 ohms. If the resistance is too high, increase the number of grounding electrodes, improve the installation method, or replace the grounding materials.

- Improve Installation Environment: Install the inverter in a dry, well-ventilated location, avoiding direct sunlight and exposure to rain. For inverters installed in humid environments, take moisture protection measures, such as installing them in waterproof cabinets and placing desiccants inside. Regularly clean the inverter and cables to keep the equipment dry.

Conclusion

In conclusion, understanding and addressing common inverter faults is essential for maintaining the performance, safety, and longevity of your photovoltaic system. By being proactive in identifying issues such as abnormal input voltage, output voltage instability, or insulation resistance faults, you can mitigate potential risks before they escalate.

Remember, these solutions are not just for professionals but are practical for every user aiming to maximize system reliability. If you encounter persistent issues, consulting with an expert can ensure your system’s health and efficiency for years to come. How often do you check your inverter’s performance, and are you ready to take action? Let’s keep those systems running smoothly!

- Next:How to Properly Charge LiFePO4 Batteries: A Complete Guide

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

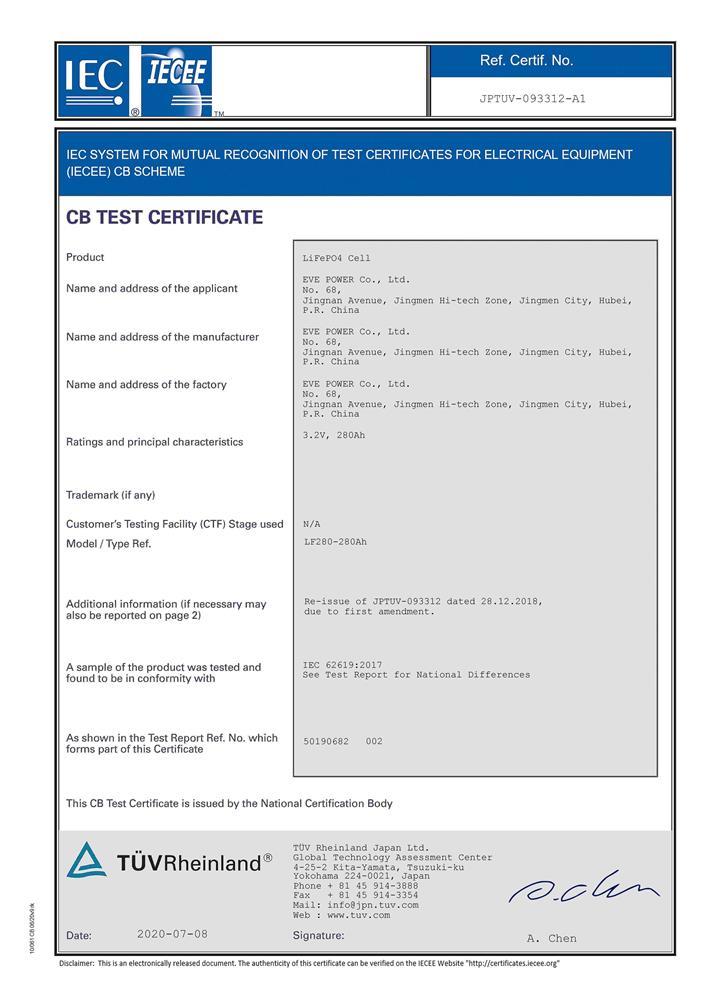

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia