Blog

4680 Battery Revolution: The Cylindrical Cell Dominating Future

2025-06-03 | Calvin

As the world transitions to cleaner energy, lithium-ion batteries are becoming the backbone of electric vehicles (EVs) and energy storage systems. Among the various battery formats—prismatic, cylindrical, and pouch cells—the 4680 cylindrical cell is poised to lead the charge, transforming the industry with groundbreaking technological innovations. This shift represents a pivotal moment in battery manufacturing, setting the stage for the next generation of EVs.

Understanding the Key Battery Formats: Technical Insights and Market Trends

| Parameter | Prismatic | Cylindrical | Pouch |

|---|---|---|---|

| Pack Efficiency | 70% (Industry Leader) | 65% | 60% |

| Production Rate | 10-20 units/min | 200 units/min | <10 units/min |

| Energy Density | Medium | Medium | High (+15% Theoretical) |

| Thermal Runaway Risk | High (Rigid Shell Expansion) | Low (Directional Venting) | Medium (Aluminum Laminate Protection) |

The lithium-ion market has seen significant shifts in the share of each battery format over the years. Prismatic cells were the dominant player with over 60% market share before 2017, but cylindrical cells, particularly Tesla's 21700 format, surged to 51% by 2020. This was largely driven by Tesla’s expansion. While prismatic cells continue to lead due to their pack efficiency, the 4680 format is fast emerging as a game-changer, signaling the dawn of a new technological era in battery production.

Tesla's 4680 Cell: Defining the Future of Battery Technology

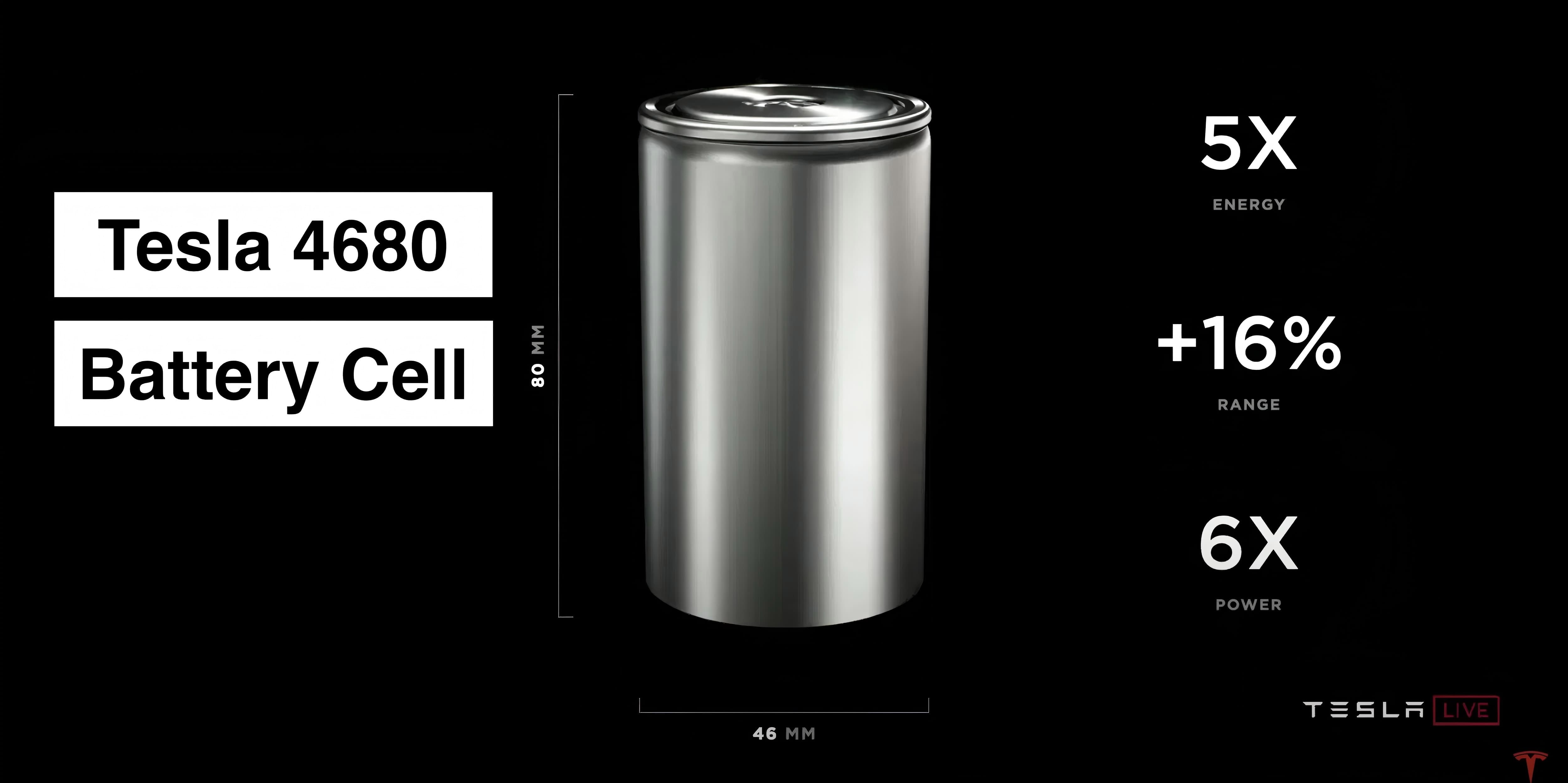

1. Optimized Geometry for Enhanced Performance

Tesla’s approach to optimizing battery design led to the development of the 4680 cell, with a 46mm diameter offering a substantial volume increase of 5.48 times compared to the 21700 cell. This optimization reduces the number of cells required in a vehicle's battery pack (960 cells for the Model Y), which in turn lowers Battery Management System (BMS) complexity by 82%. The flexible height options of the 4680 also allow it to be adapted to a variety of vehicle designs, with options like BMW's 4695/46120 variants.

2. Full-Tab Technology: Revolutionizing Battery Performance

- Electron Path Reduction: From 800-1000mm to just 80mm, drastically improving charge and discharge rates.

- Internal Resistance: A significant 90% reduction, from 20mΩ to 2mΩ, resulting in more efficient energy use.

- Fast-Charging Capabilities: With a 4C charging rate, the 4680 can achieve 80% charge in just 15 minutes.

- Thermal Management: Improved thermal control reduces temperature fluctuations from 60°C to just 20°C, enhancing battery longevity and safety.

3. Dry Electrode Technology: A Game Changer for Production and Cost

The shift from wet coating to dry electrode technology is one of the most significant innovations brought by the 4680 format:

- Cost Efficiency: This new process reduces production costs by 12-18% by eliminating solvent recovery.

- Production Throughput: Tesla’s Maxwell patent portfolio enables a 7x increase in throughput, significantly boosting production capacity.

- Energy Density: The introduction of silicon anode compatibility results in an energy density of 400Wh/kg, pushing the boundaries of energy storage.

Advancements in Core Materials for 4680 Cells

- Cathode: The new NCMA Quadruple System (with 90% nickel content) increases energy density and performance.

- Anode: A silicon-carbon composite anode material offers an initial efficiency greater than 92%, enhancing the overall battery lifespan.

- Electrolyte: The introduction of LiFSI concentration as a 15% additive further improves the efficiency and safety of the battery.

Auxiliary Material Innovations

- Separator: Aramid coating ensures the separator can withstand up to 300°C of thermal stress, increasing safety.

- Conductive Agent: Single-Walled Carbon Nanotubes (SWCNT) improve the network density by 30%, enhancing the overall conductivity.

- Housing: The use of nickel-plated steel provides a compressive strength of 180MPa, ensuring structural integrity under stress.

Scaling Production: Meeting the Demands of the Future

1. Production Capacity and Timeline

As the 4680 technology matures, companies are ramping up production:

- Tesla Giga Texas: Expected to reach 1.2 million cells per week by the end of 2023, equating to 8GWh of annual output.

- CATL: Planning for a 40GWh capacity, aligned with BMW’s supply contracts.

- EVE Energy: Aiming for a 10GWh production line by the second half of 2023.

2. Cost Reduction and Affordability

The 4680 cells are expected to significantly lower energy costs:

- 18650 (2012): $210/kWh

- 21700 (2020): $135/kWh

- 4680 (2025 estimate): $85/kWh, marking a 37% reduction in energy costs.

Expanding Beyond Automotive: The 4680 in Energy Storage

The 4680 format is not just revolutionizing electric vehicles; it’s also paving the way for advanced energy storage systems:

- Tesla Megapack: The integration of 4680 cells in Tesla's Megapack allows for 12,000 charge cycles, ensuring long-lasting, high-performance storage.

- CATL TMF Technology: This technology integrates cells directly into racks, reducing system complexity and cost.

- Cost Benefits: The system cost of energy storage using 4680 cells is expected to be $25/kWh lower than that of traditional prismatic systems, providing substantial savings for large-scale energy projects.

Conclusion: The Road Ahead

The 4680 battery is not just a step forward in the evolution of electric vehicle technology; it marks a revolution in battery design and manufacturing. From improved energy density to lower production costs, the 4680 format is setting new standards for the entire industry. As production scales up, the shift toward 46-series cells will reshape the market, driving a new wave of innovation and energy efficiency. By 2025, as production surpasses 200GWh, Tesla’s Austin Gigafactory will stand as a symbol of this technological transformation, ushering in an era of unprecedented advancements in both automotive and energy storage solutions.

With the 4680 battery, the future of electric vehicles and energy storage is not just brighter—it’s more sustainable, efficient, and cost-effective than ever before.

- Next:Three Common Inverter Faults and Solutions

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

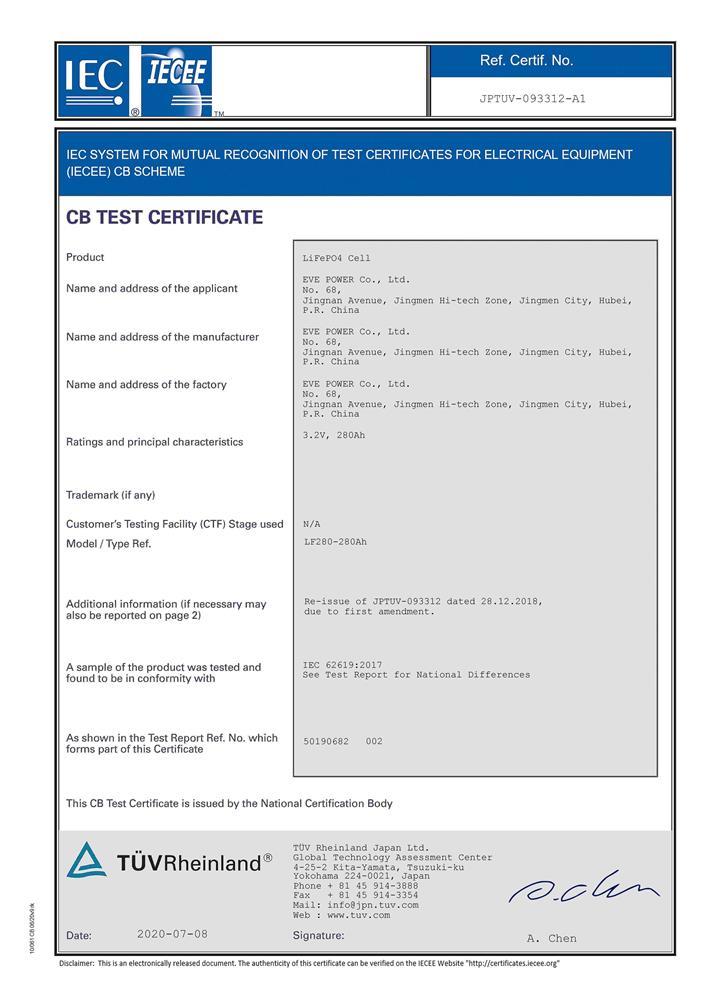

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia