Blog

What Are the Differences Between Energy Storage Battery BMS and Power Battery BMS?

2025-05-26 | Calvin

The Battery Management System (BMS) is essentially a battery caretaker, performing critical functions such as ensuring safety, extending lifespan, and estimating remaining capacity. It is an indispensable component for both power and energy storage battery packs, significantly enhancing battery life and reducing losses caused by battery damage.

Energy storage battery management systems are very similar to power battery management systems. Most people are unaware of the differences between them. Below, we briefly outline the distinctions between power battery BMS and energy storage battery BMS.

1. Different Positions in Their Respective Systems

In an energy storage system, the energy storage battery only interacts with a high-voltage energy storage converter. The converter draws power from the AC grid to charge the battery pack, or the battery pack supplies power to the converter, which then converts the electricity back to the AC grid.

The communication and battery management system in an energy storage system primarily exchanges information with the converter and the energy storage station's dispatch system. On one hand, the BMS sends critical status information to the converter to determine high-voltage power interaction conditions; on the other hand, it provides comprehensive monitoring data to the Power Conversion System (PCS) of the energy storage station.

In contrast, an electric vehicle BMS interacts energy-wise with the motor and charger under high voltage. During charging, it communicates with the charger, and throughout operation, it exchanges detailed information with the vehicle controller.

2. Different Hardware Logic Structures

Energy storage management systems typically adopt a two- or three-tier hardware architecture, with larger systems favoring three-tier management. Power battery management systems, however, usually have either a single-tier centralized or two-tier distributed structure, rarely extending to three tiers. Small vehicles mainly use centralized BMS, while larger applications employ two-tier distributed power battery management systems.

Functionally, the first and second-tier modules of an energy storage BMS are equivalent to the first-tier acquisition module and second-tier main control module of a power battery BMS. The third tier in energy storage BMS is added to handle the massive scale of energy storage batteries. This additional layer translates to higher computational power and more complex software algorithms in the BMS.

3. Differences in Communication Protocols

Energy storage BMS primarily uses the CAN protocol for internal communication, but for external communication—particularly with the energy storage station's dispatch system (PCS)—it often employs Internet protocols like TCP/IP.

In electric vehicles, the broader environment relies on the CAN protocol, with internal CAN used for communication within the battery pack and vehicle CAN for communication between the battery pack and the vehicle.

4. Different Core Battery Types and Parameter Variations

Considering safety and cost, energy storage stations often opt for lithium iron phosphate (LFP) batteries when choosing lithium-based solutions, with many stations using lead-acid or lead-carbon batteries instead. In contrast, electric vehicles predominantly use LFP or ternary lithium batteries.

The differences in battery types lead to significant variations in external characteristics, making battery models non-interchangeable. BMS parameters must be tailored to specific battery cores, and even cores of the same type from different manufacturers require unique parameter settings.

5. Different Threshold Setting Trends

Energy storage stations have ample space to accommodate more batteries, but some remote locations face transportation challenges, making large-scale battery replacements difficult. These stations prioritize long battery life and reliability, setting relatively lower current limits to avoid overloading. Energy and power density requirements are less stringent, with emphasis placed on cost-effectiveness.

Power batteries, however, are expected to perform at their maximum capacity within the limited space of a vehicle. System parameters are often set close to battery limits, which can be harsh on the batteries.

6. Different State Parameter Calculation Requirements

State of Charge (SOC) is a critical parameter for both systems. However, unlike power batteries, energy storage systems lack standardized requirements for BMS computational capabilities. Additionally, the stable and spacious environment of energy storage systems makes minor deviations less noticeable. Thus, energy storage BMS demands lower computational power, resulting in lower per-cell management costs compared to power battery BMS.

7. Energy Storage BMS Benefits from Passive Balancing

Energy storage stations place high demands on balancing capabilities. Due to the large scale of battery modules and multiple cells connected in series, voltage imbalances can significantly reduce overall capacity—the more cells in series, the greater the capacity loss. From an economic standpoint, effective balancing is crucial for energy storage stations.

Moreover, the ample space and good heat dissipation in energy storage systems allow passive balancing to perform effectively. Larger balancing currents can be used without overheating concerns, making low-cost passive balancing an ideal solution for energy storage applications.

- Next:5 Compelling Reasons to Choose LiFePO4 Prismatic Cells

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

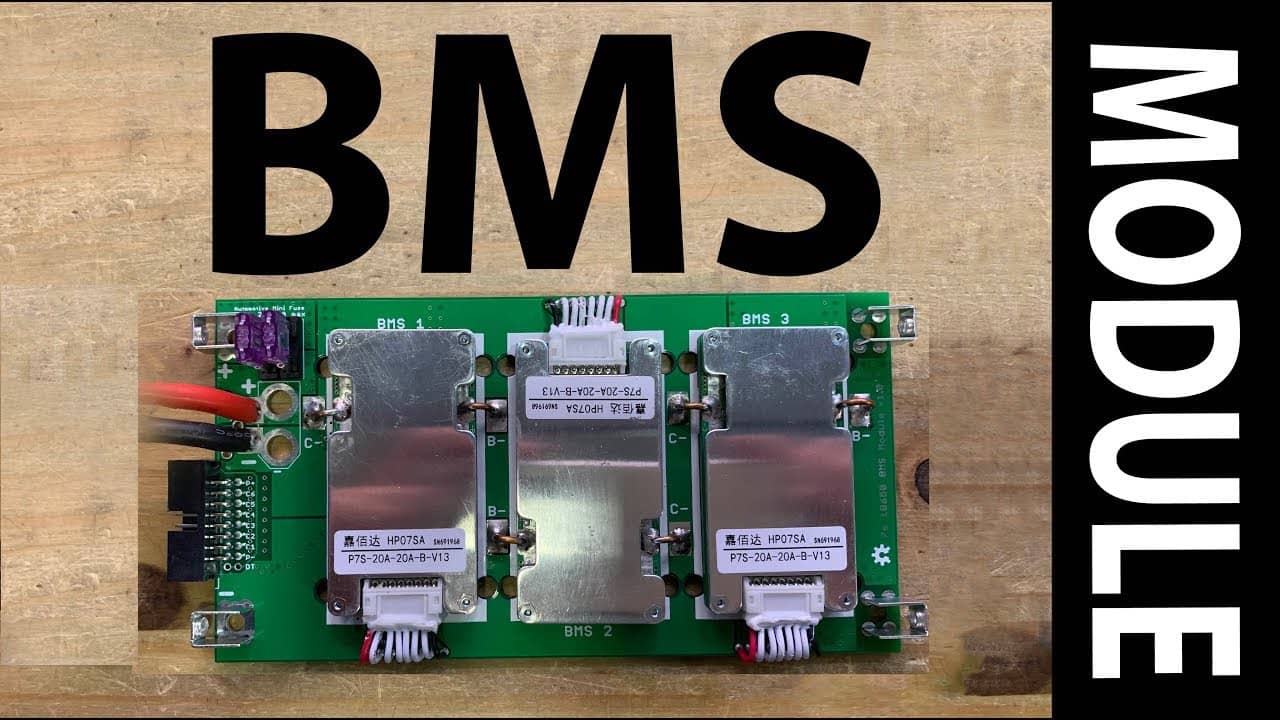

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

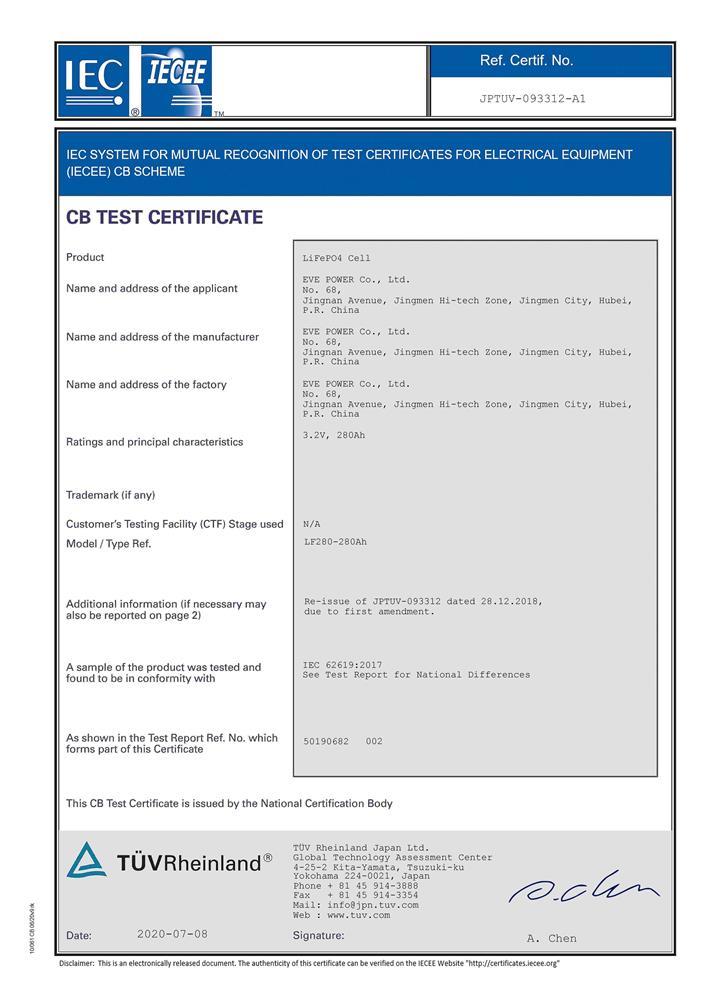

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia