Blog

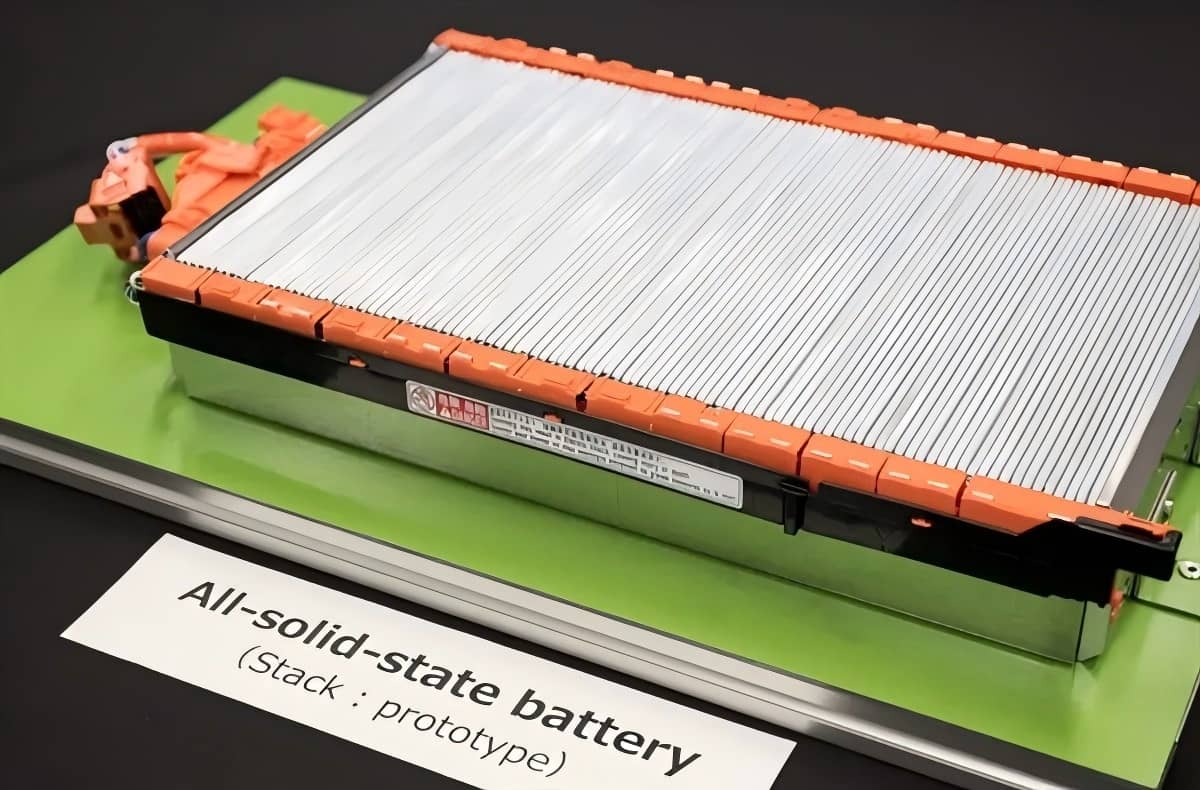

CATL's All-Solid-State Battery Enters Sample Verification Phase

2025-08-16 | Calvin

We have exclusively learned that CATL has significantly increased its R&D investment in all-solid-state batteries this year, expanding its dedicated research team to over 1,000 personnel.

Currently focusing on the sulfide electrolyte route, CATL has recently progressed to the 20Ah sample trial production stage. According to an informed source, CATL's current solution can achieve an energy density of 500 Wh/kg for ternary lithium batteries - a 40%+ improvement over existing batteries - though charging speed and cycle life still fall short of expectations.

The Evolution of Sample Production

The development of all-solid-state battery prototypes typically begins with 1Ah cells before gradually scaling up capacity. The 1Ah stage serves to evaluate fundamental material properties; 10Ah samples test single-cell performance; while reaching 20Ah signifies the preliminary finalization of the battery design and transition to production process exploration.

In April, CATL's Chief Scientist Wu Kai revealed at an international battery technology conference that the company had established a 10Ah all-solid-state battery performance verification platform, with technological advancements achieved in cathode/anode materials, processes, and manufacturing equipment.

Now progressing to 20Ah trial production - matching the capacity of current EV pouch cells - CATL faces the critical challenge of resolving safety and performance issues at this stage. Success here would primarily leave manufacturing engineering obstacles, which can be addressed through increased manpower and experimentation.

Ambitious Development Timeline

Chairman Robin Zeng has categorized solid-state battery progress into 9 levels, stating at September's power battery conference that CATL currently stands at Level 4, targeting Levels 7-8 by 2027 for small-batch production.

This timeline aligns with competitors like Toyota, LG Energy Solution, and Samsung SDI, slightly outpacing BYD. However, Zeng made an unusually bold claim in September: "Compared with competitors, CATL's research is 'second to none'."

This confidence stems from unprecedented investment. All-solid-state batteries represent the lithium battery industry's ultimate form, yet only Toyota maintained consistent R&D efforts over the past 30 years, with slow progress.

"With 1,000 staff at an estimated ¥1 million per head in annual costs, that's ¥1 billion just in salaries. Most solid-state battery companies couldn't even afford to build laboratories with budgets in the hundreds of millions," remarked an industry insider.

From Follower to Pioneer

Energy density remains batteries' most critical performance metric. Over three decades, industry leaders from Sony to Panasonic to CATL have increased lithium battery energy density from 120Wh/kg to about 320Wh/kg.

Unlike Moore's Law in semiconductors, battery improvements don't follow predictable doubling patterns. Global lithium battery output has grown tenfold in five years while energy density increased less than 30%.

Current liquid lithium batteries approach their theoretical limit (350Wh/kg), offering marginal improvements - perhaps 30 more smartphone minutes or 50 extra EV kilometers per charge. Elon Musk estimates electric passenger aircraft require at least 450Wh/kg energy density.

The Solid-State Advantage

Solid-state batteries replace liquid electrolytes (mainly lithium hexafluorophosphate) with solid alternatives, enabling safer use of higher-energy lithium metal anodes (replacing graphite) and high-nickel ternary cathodes, potentially doubling energy density beyond 700Wh/kg.

While most major battery firms maintained minimal solid-state R&D teams (often just dozens of engineers) until recently, CATL began serious exploration in 2016 by recruiting Dr. Liang Chengdu, a 10-year veteran of Oak Ridge National Laboratory, to lead sulfide solid-state battery research.

Initially, the team numbered under 100, focused on tracking global advancements. As recently as late 2022, CATL hadn't significantly increased investment. Wu Kai expressed skepticism last year about near-term commercialization: "If Toyota claimed mass production today, I'd be doubtful. No one currently has that capability."

The 2027 Target

This March marked a turning point when Wu Kai publicly shared CATL's progress. By September, Zeng committed to small-scale production by 2027. While Toyota has repeatedly delayed its solid-state timeline (now also targeting 2027), and startups promote semi-solid transitional products, industry observers consider CATL's roadmap more credible.

CATL has recruited dozens of technical experts from solid-state startups and Chinese Academy of Sciences this year. Zeng now receives monthly solid-state battery updates, telling his team: "Bring me only the problems - I'll solve them."

Concurrently, Chinese ministries have allocated over ¥6 billion in subsidies to six companies including CATL, BYD, and Geely, with partial funding contingent on technical progress, targeting 2027 small-scale production.

Technical Challenges

CATL's sulfide route mirrors Toyota's approach, which Wu Kai considers the highest-performance, fastest-to-market option. The four primary challenges:

- Interface Contact: Solid electrolytes create gaps between electrodes, reducing ion flow and cycle life

- Lithium Dendrites: Metallic lithium deposition forms dangerous spikes that can short-circuit cells

- Sulfide Sensitivity: Reacts with air moisture, producing toxic gas and reducing conductivity

- Manufacturing: Requires completely new production processes

CATL has developed multi-layer cathode encapsulation to stabilize interfaces, proprietary binders to maintain conductivity, and can now apply 500MPa pressure (5x Mariana Trench levels) to ensure component contact.

Current prototypes achieve 230mAh/g cathode capacity (key to energy density) and 6,000 cycles, though capacity fluctuates during cycling. For dendrites, CATL uses "sponge-like" materials to fill gaps and alloy coatings to promote even lithium deposition.

Sulfide electrolyte stability now reaches -40°C dew point (matching semiconductor cleanrooms), versus the industry's previous -60°C (near Martian surface conditions) requirement, significantly reducing production costs.

Manufacturing Breakthroughs

CATL has advanced dry electrode and isostatic pressing technologies but still faces engineering challenges. Maintaining operational pressure on finished batteries requires new packaging solutions.

A startup technical director estimates CATL could achieve 0.5GWh production capacity by 2027 - enough for thousands of EVs - given its unprecedented investment. "With sufficient funding, they'll likely accelerate the timeline," they noted.

Strategic Imperative

CATL's aggressive move reflects business necessity. While historically reinvesting half its profits into R&D, recent slowing technological gains have diminished returns. Despite outspending competitors #2-6 combined, CATL's domestic market share has dropped from 55% to about 40% amid intense price competition.

As the industry transitions from technological differentiation to commoditization, CATL must push boundaries to maintain leadership. The solid-state battery race represents its best chance to redefine the market.

- Next:Why LiFePO4 (LFP) Batteries Usually Outperform Sealed Lead-Acid (SLA)

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

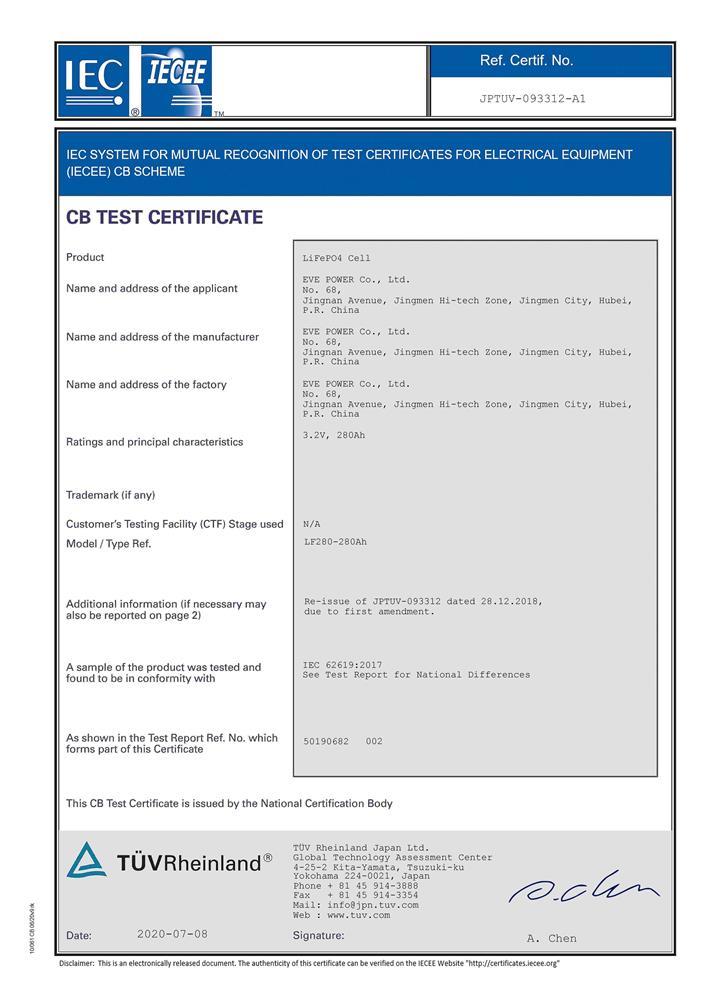

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia