Blog

Battery Reconditioning Guide

2025-05-15 | Calvin

Tired of constantly replacing expensive batteries? Whether it's your car refusing to start, your laptop dying too fast, or your tools losing power mid-job — you're not alone. In fact, most batteries can be revived instead of replaced. This 2025 guide shows you exactly how professionals do it — no fluff, just step-by-step tips that work.

What Is Battery Reconditioning?

Battery reconditioning is the process of restoring a battery to its optimal performance level. Over time, batteries lose their ability to hold a charge due to factors like age, usage patterns, and environmental conditions. Reconditioning aims to reverse these effects, allowing the battery to regain its capacity and prolong its lifespan.

Why Recondition Instead of Replace?

- Save Money: Reviving a car battery can cost as little as $5–$20, compared to $100–$300 for a new one.

- Eco-Friendly: Reduce electronic waste and minimize the need for new battery production.

- Improve Performance: Reconditioned batteries often perform better than their degraded counterparts.

How Do Batteries Work?

Batteries consist of electrochemical cells that convert chemical energy into electrical energy. When a battery discharges, a chemical reaction occurs, releasing electrons that generate electricity. Over time, these reactions can lead to issues such as sulfation in lead-acid batteries or dendrite formation in lithium-ion batteries, which can significantly reduce capacity. Understanding these processes gives insight into why reconditioning is necessary.

Signs Your Battery Needs Reconditioning

- Reduced Run Time: Devices run out of power more quickly than usual.

- Slow Charging: Noticeable delays in charging time.

- Overheating: Excessive heat during charging or discharging.

- Physical Damage: Swelling or leaking indicates severe problems.

Tools Needed for Battery Reconditioning

- Multimeter: To measure voltage and check for cell balance.

- Battery Charger: A smart charger designed for your specific battery type.

- Desulfator (for lead-acid): A device intended explicitly for desulfation.

- Safety Gear: Gloves and goggles are essential for protection.

- Distilled Water: For maintaining electrolyte levels in flooded lead-acid batteries.

How to Recondition a Lead-Acid Battery in 5 Steps

- Safety First: Wear gloves and goggles to protect against acid spills or electrical shocks.

- Check Voltage: Use a multimeter to check the voltage of each cell.

- Desulfation Process: Connect the desulfator as per the manufacturer's instructions to break down lead sulfate crystals.

- Equalization Charge: Apply a controlled overcharge to balance the cells and restore capacity.

- Water Addition: For flooded lead-acid batteries, check electrolyte levels and add distilled water as needed.

How to Recondition a Lithium-Ion Battery in 5 Steps

- Safety Precautions: Wear safety gear before working with lithium-ion cells.

- Check Cell Balance: Use a multimeter to measure each cell’s voltage within the pack.

- Use a Balancing Charger: Connect your battery pack to a charger designed for lithium-ion cells to ensure even charging.

- Cycle Charge/Discharge: Fully charge and then fully discharge the battery several times to restore capacity.

- Test Performance: After cycling, measure capacity again with a load test to verify improvements.

Common Mistakes in Battery Reconditioning

- Neglecting Safety Precautions: Always prioritize safety by wearing protective gear.

- Using Incorrect Chargers: Ensure you're using chargers compatible with your specific battery type.

- Skipping Tests: Regularly test voltage and performance throughout the process.

Final Thoughts

Reconditioning your batteries isn't just smart — it's empowering. With the right tools, a bit of patience, and this guide, you can save hundreds of dollars, reduce waste, and stay powered up. Try your first battery today, and if you found this guide helpful, share it with a friend who's always charging!

FAQs About Battery Reconditioning

What types of batteries can be reconditioned?

You can recondition 6 common types: lead-acid (car/marine), lithium-ion (laptop/phone), NiCd (power tools), NiMH (cameras), AGM (solar systems), and gel cell batteries (medical devices).

How long does battery reconditioning take?

Most batteries require 4-12 hours for full desulfation. Car batteries may need 24-48 hours. Lithium-ion batteries typically improve after 3-5 charge cycles.

Is battery reconditioning safe for beginners?

With proper precautions, lead-acid battery reconditioning has a 95%+ safety rate. Lithium-ion battery reconditioning requires expertise—only attempt it if you understand battery chemistry risks.

How much capacity can restoration achieve?

Properly reconditioned batteries regain 70-90% capacity. Lead-acid batteries show an 85% success rate, and lithium-ion average 65-75% depending on age.

- Next:How Much Does a Car Battery Weigh?

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

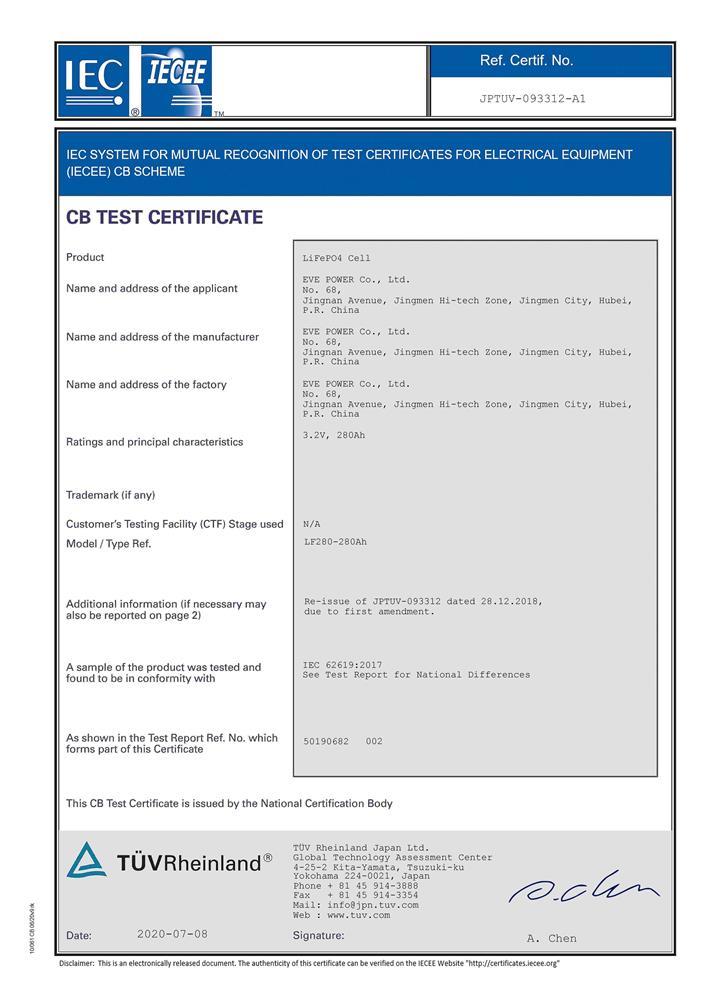

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia