Blog

BMS Fault Troubleshooting: Common Fault Cases and Solutions

2025-06-04 | Calvin

As battery technology continues to evolve, Battery Management Systems (BMS) have become a crucial component in modern electric vehicles (EVs) and energy storage systems. Not only do they ensure efficient utilization of batteries, but they also protect against overcharging, over-discharging, and other issues, thus extending battery lifespan. However, due to the complexity of their functions, BMS faults are relatively common. In this article, we will delve into common BMS faults, providing detailed troubleshooting methods and solutions to help you address various issues and ensure system stability.

1. Functions and Role of the Battery Management System (BMS)

Before diving into fault analysis, let's briefly review the core functions of a BMS. The role of the Battery Management System goes beyond just battery monitoring; it involves protection, diagnostics, balancing, and thermal management:

- Battery Protection: The BMS monitors parameters such as voltage, temperature, and current to prevent overcharging, over-discharging, and ensure battery safety.

- Charging Control: The BMS controls the charging process, including switching between slow and fast charging modes to optimize battery performance and longevity.

- Battery Status Monitoring: The BMS tracks the state of charge (SOC), state of health (SOH), and state of function (SOF), adjusting the battery’s operating mode accordingly.

- Fault Diagnosis and Warning: When a fault occurs, the BMS generates real-time alerts and provides fault information for timely repairs.

- Thermal Management: The BMS regulates the cooling system to maintain the battery within an optimal temperature range, avoiding performance degradation or safety risks caused by extreme temperatures.

2. BMS Fault Analysis Methods

When a BMS fault occurs, the troubleshooting process can be complex. However, by applying appropriate methods, you can quickly pinpoint the issue. Below are several common fault analysis methods:

1. Observation Method

Start by checking if any alarms or fault codes are displayed on the system. The alarm icons or fault codes can give you a preliminary idea of where the problem lies.

2. Elimination Method

When the system exhibits interference phenomena, you can eliminate each component one by one to see if a specific part is causing the issue.

3. Substitution Method

If you encounter abnormal temperature or voltage readings, you can swap modules or wiring to determine whether the issue is with a specific module or another hardware component.

4. Environmental Check

Sometimes, the issue may be as simple as an unconnected power supply, a switch that hasn’t been turned on, or incomplete wiring. Perform a thorough check for these details.

5. Software Upgrade Method

If issues arise after a system upgrade, try rolling back to a previous stable version to see if the problem is related to the software update.

6. Data Analysis Method

By analyzing the data stored in the BMS, especially the messages on the CAN bus, you can quickly identify the root cause of the fault.

3. Common BMS Fault Cases and Solutions

Now, let's dive into 16 common BMS fault cases and provide solutions for each one. Each case includes the possible cause and troubleshooting steps.

1. Entire System Does Not Work After Powering Up

- Possible Cause:

- Power supply issues, short circuit or broken wires, no output from the DC-DC converter.

- Troubleshooting:

- Check if the external power supply is functioning correctly and providing sufficient voltage and power.

- Inspect wiring for any short circuits or disconnections.

- If the power supply and wiring are normal, check the DC-DC converter for output voltage and replace the module if necessary.

2. BMS Cannot Communicate with ECU

- Possible Cause:

- BMU main control module is not working, CAN signal wire is disconnected.

- Troubleshooting:

- Ensure the BMU is powered on.

- Check the CAN signal wire for proper connection and make sure the pins are seated correctly.

- Use a monitoring tool to check the data transmission on the CAN port.

3. Unstable Communication Between BMS and ECU

- Possible Cause:

- Poor external CAN bus matching or long bus branches.

- Troubleshooting:

- Check if the bus’s matching resistors are correct and ensure proper length and configuration of bus branches.

4. Unstable Internal Communication of BMS

- Possible Cause:

- Loose connectors, improper CAN wiring, or duplicate BSU addresses.

- Troubleshooting:

- Inspect the connections for looseness.

- Ensure proper resistor matching and follow correct wiring practices.

- Check for duplicate BSU addresses and adjust if necessary.

5. Insulation Detection Alarm

- Possible Cause:

- Battery or driver leakage, improper insulation module connection.

- Troubleshooting:

- Check the battery bus voltage through the BDU display module.

- Measure the insulation resistance between the battery bus and the driver.

6. Main Relay Does Not Engage After Power-Up

- Possible Cause:

- Load detection line not connected, pre-charge relay open.

- Troubleshooting:

- Check the load detection line connection.

- Inspect the pre-charge relay and resistor for open-circuit issues.

7. Data from Acquisition Module Is Zero

- Possible Cause:

- Disconnection of acquisition wires or module failure.

- Troubleshooting:

- Check the connections of the acquisition module and wiring to ensure proper signal transmission.

8. Incorrect Battery Current Data

- Possible Cause:

- Loose or damaged Hall sensor signal wires.

- Troubleshooting:

- Inspect the Hall sensor signal wire connections for stability.

- Ensure the Hall sensor power supply is functioning correctly and replace the sensor if necessary.

9. Large Temperature Difference Between Batteries

- Possible Cause:

- Loose fan plug or faulty fan.

- Troubleshooting:

- Check the fan plug connection to ensure the fan is functioning properly.

10. Battery Temperature Too High or Too Low

- Possible Cause:

- Fan failure, temperature probe damage.

- Troubleshooting:

- Check if the fan is operating correctly and verify the temperature probe's resistance is normal.

11. Relay Action Causes System Error

- Possible Cause:

- Open relay auxiliary contacts or misaligned signal cable pins.

- Troubleshooting:

- Inspect relay auxiliary contacts and ensure they are not sticking.

- Check signal wiring to ensure proper alignment of cable pins.

12. Communication Interruption Between BMU and BDU

- Possible Cause:

- Connection issues with communication line.

- Troubleshooting:

- Check wiring between BMU and BDU, ensuring no loose or broken connections.

- Replace any faulty cables and test communication again.

13. Software Fault

- Possible Cause:

- Software error or improper version.

- Troubleshooting:

- Check the software version and perform updates if necessary.

- Consult the manufacturer's troubleshooting guide for software-specific issues.

14. Battery Voltage Abnormalities

- Possible Cause:

- Faulty voltage sensor or wiring issues.

- Troubleshooting:

- Inspect the voltage sensor for damage and check the associated wiring.

4. Conclusion

In practice, different faults may require different troubleshooting strategies. Therefore, it is essential to understand common fault cases and master the corresponding solutions to ensure the stability and performance of the Battery Management System (BMS). We hope this article provides useful troubleshooting methods and practical solutions to help you maintain the system's smooth operation.

- Next:How Do You Choose the Right Battery for Your Semi-Truck: Expert Guide

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

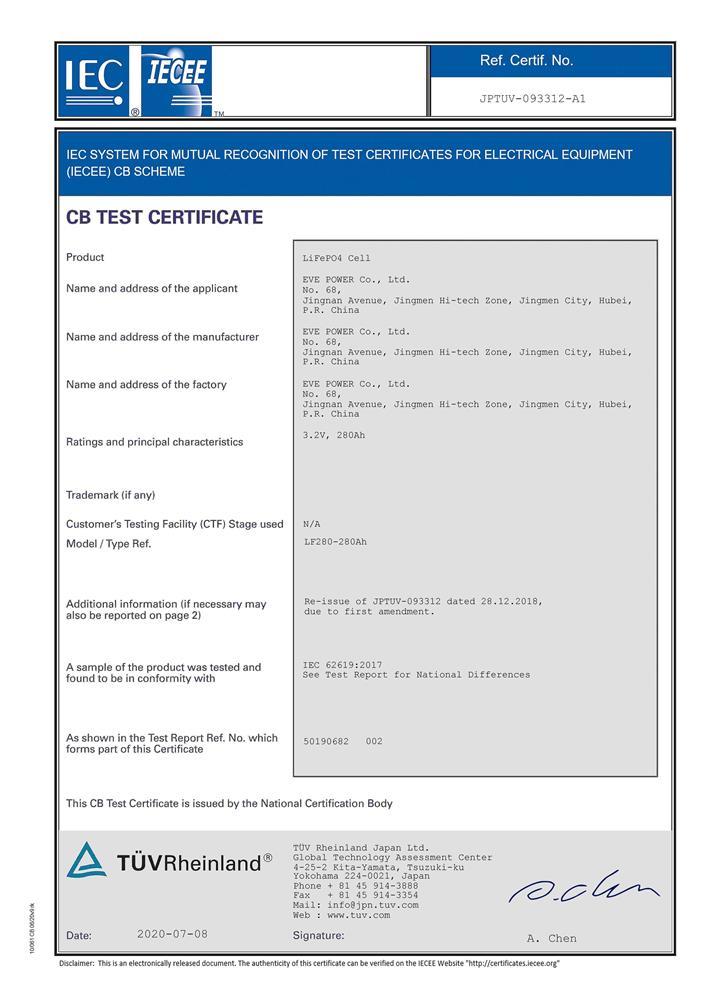

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia