Blog

Understanding Lithium Battery Internal Resistance and How to Measure It

2025-06-17 | Calvin

In today's technological era, lithium batteries serve as the power source for numerous electronic devices, making their performance crucial. The internal resistance of lithium batteries, often an overlooked parameter, actually has a profound impact on lithium battery performance. Today, let's delve into the mysteries of lithium battery internal resistance.

What is Battery Internal Resistance?

Battery internal resistance refers to the opposition encountered when current flows through the battery, comprising ohmic resistance, electrochemical polarization resistance, ion migration resistance, and other components.

Ohmic resistance primarily consists of electrode materials, electrolyte, separator resistance, and contact resistance between components, related to battery size, structure, and assembly.

Electrochemical polarization resistance and ion migration polarization resistance (collectively called polarization resistance) refer to the internal resistance caused by polarization during electrochemical reactions at the electrodes.

Different battery types exhibit different internal resistances. Even batteries of the same type may have varying internal resistances due to differences in their internal chemical characteristics. Battery internal resistance is typically very small, usually measured in milliohms (mΩ). Internal resistance is a key technical indicator for evaluating battery performance. Generally, batteries with lower internal resistance demonstrate stronger high-current discharge capability, while those with higher internal resistance have weaker discharge capacity.

From the perspective of discharge circuit principles, a battery can be modeled as an ideal power source (with zero internal resistance) in series with a small resistor (internal resistance). When connected to a light load, the voltage drop across the internal resistance is small; when connected to a heavy load, the voltage drop increases, causing some power to be dissipated as heat or complex reverse electrochemical reactions. New rechargeable batteries typically have low internal resistance, but prolonged usage leads to electrolyte depletion and reduced activity of internal chemical substances, gradually increasing internal resistance. When internal resistance becomes too high to effectively release stored energy, the battery reaches end-of-life. Most aged batteries lose their practical value due to excessive internal resistance. Therefore, we should focus more on the actual discharge capacity rather than the charge capacity.

Internal Resistance is Not a Fixed Value

The complexity lies in the fact that battery internal resistance varies with state of charge (SOC) and state of health (SOH). Technically, battery internal resistance is typically categorized into two states:

1. Charged-state internal resistance: Measured when the battery is fully charged.

2. Discharged-state internal resistance: Measured when the battery is fully discharged to the standard cutoff voltage.

Discharged-state internal resistance is generally unstable, often yielding higher measurements, whereas charged-state internal resistance is relatively stable and more meaningful for practical comparisons. Therefore, battery measurements typically use charged-state internal resistance as the standard.

Internal Resistance Cannot Be Precisely Measured by Conventional Methods

Some might recall high school physics experiments using resistor boxes to calculate battery internal resistance. However, such methods offer low precision and are only suitable for theoretical education, failing to meet practical application requirements. Battery internal resistance is extremely small (typically in micro-ohms or milliohms), with conventional measurements requiring accuracy within ±5%. Such stringent demands necessitate specialized instruments.

Industry-Standard Battery Internal Resistance Measurement Methods

In industrial applications, precise measurement of battery internal resistance requires specialized equipment. The two primary methods are:

1. DC Discharge Internal Resistance Measurement

Based on the formula R=U/I, test equipment forces the battery to conduct a large constant DC current (typically 40A–80A) for a short duration (usually 2–3 seconds), measures the voltage drop across the battery, and calculates the internal resistance.

Advantages: High measurement precision, with controlled errors potentially below 0.1%.

Disadvantages:

- Only applicable to high-capacity batteries or accumulators; small-capacity batteries cannot withstand such high instantaneous currents.

- High currents cause electrode polarization, generating additional polarization resistance, thus requiring extremely short measurement times to avoid significant errors.

- High currents may damage internal electrodes.

2. AC Voltage Drop Internal Resistance Measurement

Since a battery can be modeled as an active resistor, this method applies a fixed-frequency (typically 1kHz) and fixed-amplitude small AC current (e.g., 50mA) to the battery, samples the AC voltage response, and calculates internal resistance through rectification, filtering, and operational processing. Measurement time is extremely short (~100ms).

Advantages:

- Wide applicability—can measure almost all battery types (including small-capacity batteries) such as notebook battery cells.

- Minimal damage to batteries.

Disadvantages:

- Measurement accuracy (typically 1%–2% error) is generally inferior to DC discharge methods.

- Susceptible to ripple current and harmonic interference, requiring high noise immunity in instrument circuits.

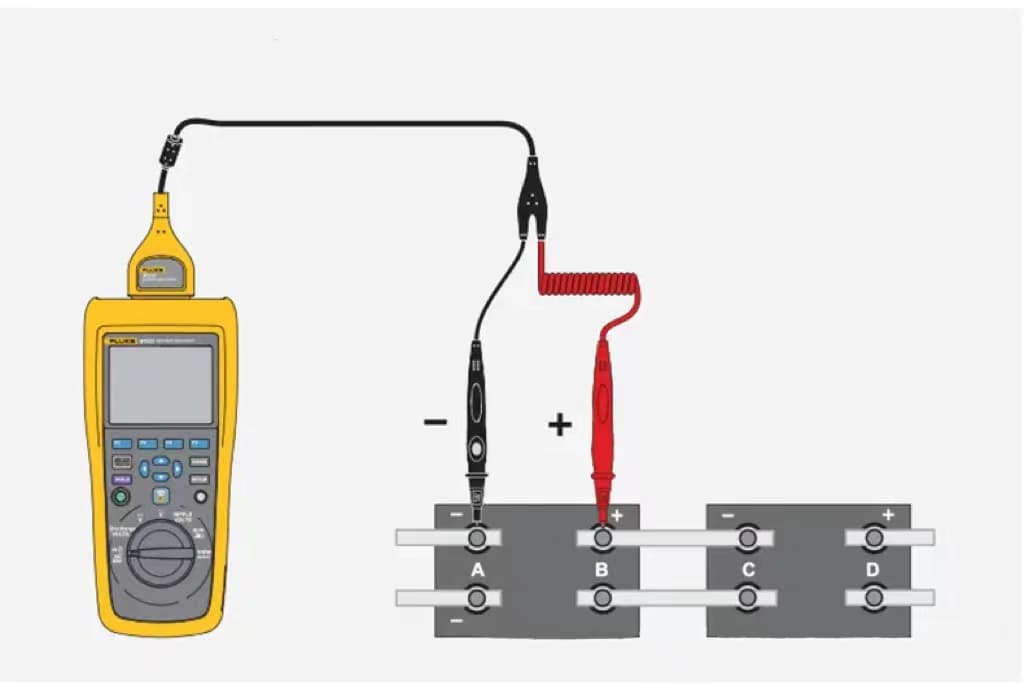

3. Instrument Errors and Connection Issues

Regardless of the method, instrument component errors and connection issues must be considered. Due to the extremely small resistances being measured, lead resistance (micro-ohm level) and contact resistance between battery terminals and leads must be accounted for. Therefore, professional battery internal resistance testers incorporate internal error compensation and feature specialized low-resistance leads and secure battery fixtures.

Impact of Internal Resistance on Lithium Battery Performance

1. Discharge Performance

Higher internal resistance causes greater voltage drop during discharge, reducing output voltage and limiting maximum current output. In high-power-demand scenarios (e.g., EV acceleration or high-load device operation), excessive internal resistance leads to performance degradation.

2. Charge Performance

High internal resistance limits charging current, slowing charge rates, extending charge times, and reducing efficiency. With fast-charging technologies becoming prevalent, reducing internal resistance is key to improving charge performance.

3. Self-Discharge Rate

Self-discharge refers to capacity loss when lithium batteries are idle due to internal chemical reactions. Increased internal resistance often accompanies or accelerates side reactions, potentially worsening self-discharge.

4. Thermal Characteristics

Heat generation during operation (I²R loss) is proportional to internal resistance (R). Higher internal resistance causes greater heat generation at the same current, raising lithium battery temperature and potentially compromising stability and safety (especially under high currents or temperatures).

5. Cycle Life

Increasing internal resistance is a key indicator of lithium battery aging. Higher internal resistance causes greater energy loss (heat) per charge-discharge cycle, reducing active material utilization and accelerating performance degradation, ultimately shortening lithium battery life.

Optimization Strategies to Reduce Internal Resistance and Improve Performance

- Material Optimization: Use high-conductivity, low-polarization electrode materials (e.g., conductive carbons, single-crystal/high-nickel cathodes) and low-viscosity, high-conductivity electrolytes/additives. Improve material purity and uniformity.

- Structural Improvements: Optimize electrode design (coating uniformity, compaction density, current collectors), reduce separator thickness (safely), and enhance electrolyte wettability to lower ohmic and interfacial resistance.

- Battery Management Systems (BMS): Precisely control charge/discharge (avoid overcharge/over-discharge/extreme currents) and maintain optimal temperatures via BMS to slow internal resistance growth.

- Advanced Thermal Management: Implement liquid cooling, forced air, or phase-change materials (PCMs) to maintain optimal operating temperatures, preventing thermal runaway and accelerated aging.

Conclusion

Many aged lithium batteries retain considerable capacity but become unusable due to excessive internal resistance—a true waste. Once internal resistance significantly increases, manual reduction is extremely difficult. "Revival" methods like high-current pulses, trickle charging, or freezing typically prove futile. Understanding these principles highlights the importance of selecting lithium batteries with inherently low internal resistance. Additionally, prolonged storage increases internal resistance; thus, regular usage is recommended to maintain electrochemical activity.

- Next:Everything You Need to Know About the BYD Blade Battery

- Previous:Tesla Battery Types: A Simple Guide for Model S, 3, X, and Y

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (22)

- Cylindrical Cell (3)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (3)

- Lithium Titanate Battery (16)

- Ternary Lithium Battery Cell (11)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (21)

- EVE Battery (29)

- LiFePO4 Battery Cell (4)

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia