News

Samsung SDI, BMW, and Solid Power Collaborate on All-Solid-State Battery Development

2025-11-07 | Calvin

As global competition in the electric vehicle (EV) industry heats up, the next major breakthrough in power battery technology—all-solid-state batteries—has reached a new milestone. On October 31, South Korean battery giant Samsung SDI officially announced a strategic tripartite agreement with Germany’s luxury automaker BMW Group and U.S. battery technology pioneer Solid Power to jointly carry out an all-solid-state battery validation project.

According to the agreement, Samsung SDI will use Solid Power’s solid-state electrolyte to supply battery cells that combine higher energy density with enhanced safety. BMW Group will take charge of developing the corresponding battery modules and packs. The three parties aim to evaluate the battery’s performance based on jointly defined parameters and requirements, and install the cells into BMW’s next-generation test vehicles for validation.

This collaboration not only marks a critical step in bringing all-solid-state batteries from lab research to real-vehicle integration but could also reshape the competitive landscape of the future high-end EV market.

A “Technical Dance” of Complementary Strengths

This partnership brings together three key players from across the industry chain, forming a clear division of technological and industrial roles.

Technology and Manufacturing: As one of the world’s leading power battery suppliers, Samsung SDI will handle the core battery cell manufacturing. Using Solid Power’s solid-state electrolyte, Samsung SDI will produce cells that deliver both high energy density and outstanding safety. In this partnership, Samsung’s engineering capabilities and large-scale manufacturing expertise serve as the bridge that transforms cutting-edge research into real-world products.

Core Materials: Solid Power, a U.S.-based technology startup, serves as the “technological cornerstone” of the collaboration. Specializing in solid-state electrolyte development, its sulfide-based electrolyte system is considered key to unlocking performance leaps. This highlights how material innovation continues to be the fundamental engine driving progress in next-generation battery technologies.

End Applications: As the final user and automaker, BMW Group will integrate these cells into battery modules and packs. More importantly, BMW will conduct comprehensive performance evaluations based on shared parameters and requirements, before installing the batteries into next-generation validation vehicles for rigorous real-world testing. This ensures that R&D efforts remain guided by actual vehicle performance, safety, and user experience needs.

This cooperation model—materials expert + battery giant + automotive leader—maximizes each participant’s strengths, forming a complete loop from materials to cells to vehicles. It significantly increases the likelihood of successful industrialization.

Challenges Yet to Be Solved

All-solid-state batteries are often called the “ultimate form” of power batteries. Their key advantage lies in replacing the flammable liquid electrolytes used in current lithium-ion batteries with non-flammable solid electrolytes.

However, the road from laboratory success to mass production remains steep. Key challenges include the ionic conductivity of solid electrolytes, the stability of solid-solid interfaces between the electrolyte and electrodes, and the high manufacturing costs. These are global technical hurdles that the industry has yet to overcome.

That’s why this tripartite validation project is so significant. It’s no longer about isolated lab breakthroughs—it’s about integrating these technologies into real, demanding vehicle environments to answer one crucial question: Can all-solid-state batteries deliver stable, safe, and cost-effective performance while meeting automotive-grade standards?

A Win-Win Partnership

Each partner stands to gain something vital from this collaboration.

For BMW Group: Facing strong competition from Tesla and the rapid rise of Chinese EV brands, BMW urgently needs a breakthrough in next-generation battery technology to maintain its leadership in the luxury car segment. By aligning with top-tier technology and manufacturing partners, BMW aims to secure its supply chain and stay competitive in the second phase of its electrification journey.

For Samsung SDI: This marks a key battle in its bid to surpass CATL and LG Energy Solution in the global battery race. Whoever achieves mass production of all-solid-state batteries first will dominate the industry narrative for the next decade. Deep collaboration with a top-tier client like BMW not only provides Samsung SDI with a trusted validation platform but also locks in potential high-value orders in the premium battery market.

For Solid Power: Partnering with industrial giants offers the most effective route to commercializing its technology. For a tech-focused startup, leveraging Samsung’s manufacturing capabilities and BMW’s vehicle platforms will greatly accelerate its journey from “prototype” to “product,” proving both its technical feasibility and commercial potential.

Conclusion

The collaboration between Samsung SDI, BMW, and Solid Power has undoubtedly injected new momentum into the global race for all-solid-state batteries. It exemplifies an innovation model driven by cross-sector cooperation.

Regardless of the final outcome, the process itself will greatly accelerate technological progress across the entire industry. We’re likely to see more such partnerships emerge in the near future.

- Next: Mr. Giant Energy Storage System Launches in Australia!

- Previous: Sunwoda’s Consumer Semi-Solid-State Battery Production Exceeds 8 Million Units

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat : 15263269227

Email : info@lifepo4batteryshop.com

All Products

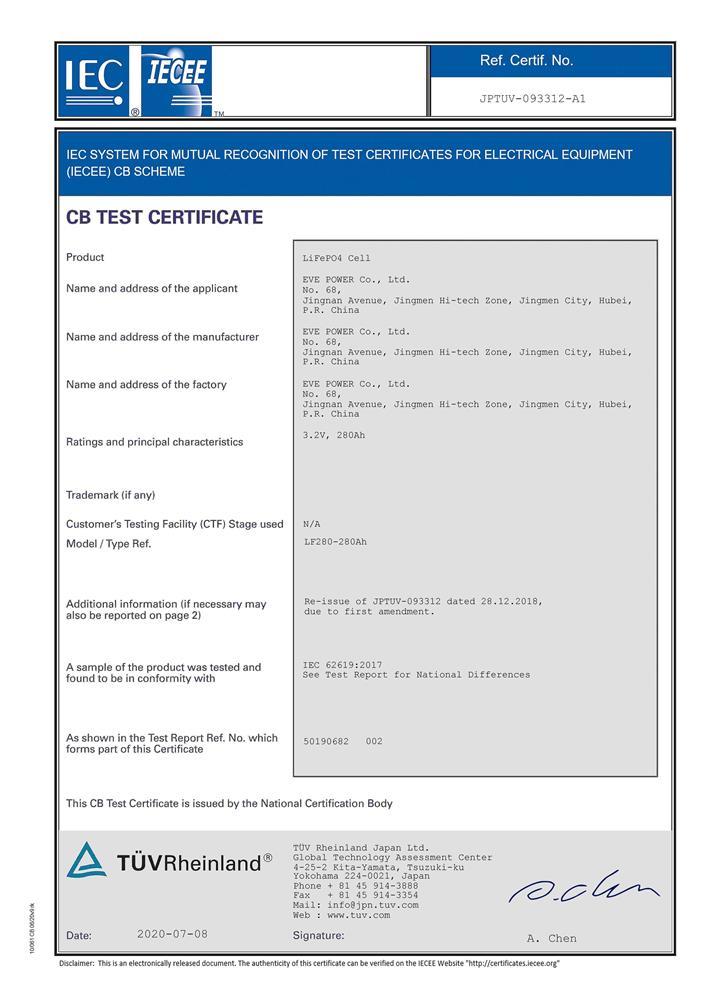

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia