Blog

What Is Lithium-ion Battery Consistency?

2025-09-07 | Calvin

Lithium-ion batteries power everything from e-bikes to motorcycles to home energy storage. But one problem that’s often ignored? cell consistency — small differences between cells that pile up and shorten pack life. If you’re building battery packs for power wheel or motorcycle applications, getting consistency right isn’t optional. It’s essential.

Below I’ll explain what battery consistency means, why it matters, the main causes of inconsistency, and practical, repeatable methods to test, sort, and match cells for reliable packs.

Table of Contents

- What “battery consistency” actually means

- How inconsistencies show up (symptoms)

- Main causes of cell inconsistency

- How to measure cell parameters (practical tests)

- How to sort (step-by-step)

- Sorting tolerance recommendations (examples)

- Assembly & system measures to maintain consistency

- Production controls that reduce initial inconsistency

- Practical considerations for real products

- Conclusion — Why sorting matters

What “battery consistency” actually means

Battery consistency describes how similar supposedly identical cells are in real-world performance. Key parameters include:

- Voltage (at rest and under load)

- Capacity (Ah)

- Internal resistance (IR) — affects heat and power delivery

- State of charge (SOC) — current charge level

- Temperature sensitivity — how performance changes with temp

- Self-discharge rate — how fast a cell loses charge sitting idle

Small differences at the start can grow with use. In a pack, the weakest cells limit the whole system — leading to quicker capacity loss, imbalance, and earlier pack replacement.

How inconsistencies show up (symptoms)

- Uneven voltage readings across cells during discharge or charge

- Faster capacity fade in some cells vs others

- Hot spots under load (cells with higher IR)

- Imbalance that the BMS struggles to compensate for

- Shorter overall pack life and unpredictable range or power

Main causes of cell inconsistency

In production

- Raw material variations (particle size, purity)

- Non-uniform slurry mixing and coating thickness

- Drying and calendaring differences

- Cell formation and early cycling inconsistencies

In assembly & use

- Poor contact or uneven busbar connections

- Thermal gradients inside the pack (some cells hotter than others)

- Different usage patterns or charge histories for reused cells

- Manufacturing tolerances and QC gaps

How to measure cell parameters (practical tests)

If you want to sort cells effectively you need reliable, repeatable measurements:

- Open-Circuit Voltage (OCV) — quick, but only gives limited info (useful for SOC rough grouping).

- Capacity test (Ah) — discharge at a chosen C-rate to a cutoff voltage and record Ah; this is the gold standard for sorting by usable capacity.

- Internal Resistance (IR) — measure with a DC load or dedicated IR tester (lower IR = better for high-power applications).

- Pulse/Load tests — apply a defined load pulse to see voltage sag (reveals IR + health).

- Cycle test — for critical builds, cycle cells several times to observe early capacity fade (time-consuming but most predictive).

- Temperature response — test at expected operating temps to flag cells with high thermal sensitivity.

Pro tip: Use consistent test conditions (same temp, same C-rate, same equipment). Variability in the test itself will mask real differences.

How to sort (step-by-step)

This is a practical workflow you can apply in production or a workshop:

- Initial visual & voltage screening

- Remove obviously damaged cells.

- Measure OCV after resting (30–60 min) and discard extreme outliers.

- Pre-conditioning

- Bring all candidate cells to a common SOC (e.g., 50% or manufacturer recommended) before capacity/IR tests.

- Capacity testing

- Discharge each cell at a chosen C-rate to the same cutoff voltage. Record Ah.

- Create capacity “bins” (e.g., within ±1–2% or ±50–100 mAh depending on application).

- Internal resistance sorting

- Measure IR and bin cells (high-power packs need tighter IR matching).

- If a cell has acceptable capacity but high IR, it may still be unsuitable for high discharge roles.

- Multi-parameter matching

- Combine the bins: pick cells that match across capacity + IR + OCV.

- For best results use multi-parameter matching (voltage ± SOC, capacity ±%, IR ±Ω).

- Dynamic feature matching (advanced)

- Use pulse/load curves and SOC slope behavior to match cells that behave similarly under realistic loads. This approach is more predictive for motorcycle/power wheel use.

- Labeling & traceability

- Label each cell with batch/ID and bin. Keep a record for warranty/quality control.

- Final pack assembly with balancing

- Assemble matched cells in modules. Use a BMS and passive/active balancing as required.

Sorting tolerance recommendations (examples)

- High-power (motorcycle, e-bike): capacity within ±1–2%, IR within a tight band (as low as practical).

- Energy storage (stationary): capacity within ±3–5% may be acceptable, IR tolerance can be looser.

- Reused/recycled cells: tighten tolerances and increase cycle testing before assembly.

(Adjust tolerances based on your product’s safety and performance goals.)

Assembly & system measures to maintain consistency

- BMS with balancing — use a BMS that supports the pack chemistry and can balance cells during charge and in use.

- Thermal management — ensure even temperature across the pack (heat spreaders, cooling channels).

- Mechanical design — uniform pressure/contact on terminals to avoid micro-resistance differences.

- Matched grouping by module — build modules from matched cells and then combine modules, not random cells.

- Monitoring & maintenance — log cell voltages, temp, cycles; flag cells that diverge for replacement.

Production controls that reduce initial inconsistency

- Strict raw material specs and vendor control

- Tight process control for slurry mixing, coating, drying

- Standardized formation cycles and aging protocols

- Inline QC: measure capacity/IR on sample cells and at key production stages

- Lot traceability so any issue can be quarantined by batch

Practical considerations for real products

- Safety first: never push cells beyond manufacturer specs to force matching. Always follow the cell datasheet.

- Economics: tighter matching and testing costs more time and equipment — balance cost vs. required reliability.

- Recycled cells: they’re cheaper but need much stricter testing and smaller tolerances.

- Chemistry choice: LiFePO4 cells tend to have different IR/thermal behavior than NMC — choose chemistry that fits your application and tune matching methods accordingly.

Conclusion — Why sorting matters

Cell inconsistency is a silent killer of battery pack reliability. With the right testing, sorting, and system design — capacity and IR tests, multi-parameter matching, thermal and BMS strategies — you can significantly extend pack life and improve safety and performance. For motorized applications like power wheels and motorcycles, tight matching and robust thermal/BMS control are especially important.

- Next:How to configure the battery in a home energy storage system?

- Previous:How to Care for and Maintain Your LiFePO4 Battery

Contact Details

Lithium LiFePO4 Batteries and Lithium LiFePO4 Cells Supplier - LiFePO4 Battery Shop

Contact Person: Miss. Elena Wang

WhatsApp : +8615263269227

Skype : +8615263269227

WeChat :15263269227

Email : info@lifepo4batteryshop.com

All Products

- A123 Battery (5)

- Sinopoly Battery (7)

- GBS Battery (16)

- CALB Battery (9)

- Cylindrical Cell (1)

- Energy Storage System (0)

- Battery Management System (2)

- Sodium ion Battery Cell (1)

- Lithium Titanate Battery (8)

- Ternary Lithium Battery Cell (1)

- REPT Battery (8)

- BYD Battery (2)

- CATL Battery (14)

- Thunder Sky Winston Battery (20)

- EVE Battery (29)

- LiFePO4 Battery Cell (2)

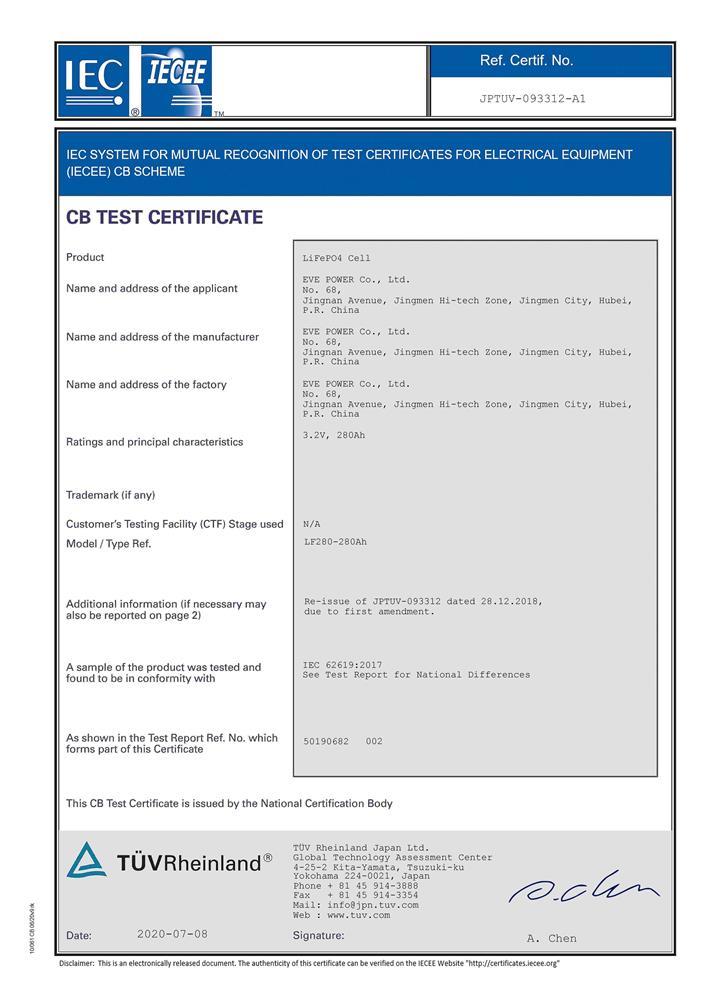

Certification

Customer Reviews

- I have fond memories of our meeting in Shanghai with LiFePO4 Battery Shop Elena. Your company left a strong impression on me with its impressive growth and professionalism. We both value straightforwardness and honesty, which I believe are the most important qualities in any partnership. I am confident that we can build a successful collaboration based on these shared values. —— Robert from USA

- I've been working with LiFePO4 Battery Shop for years, and their reliability is unmatched. While other suppliers frequently change sales teams, LiFePO4 Battery Shop has consistently provided exceptional service with a stable team. Their commitment to quality and customer support truly sets them apart. —— Henry from Australia